Epoxy resin anticorrosive steel pipe advantages

Many users have encountered this problem before, what are the characteristics of epoxy anticorrosive steel pipes that can make their status so popular in engineering projects

His application area is not different, we take this question, together with the epoxy resin anticorrosive steel pipe manufacturers to simply explain what is going on

Epoxy resin anticorrosive steel pipe properties

Epoxy resin anticorrosive steel pipe has a strong bonding force, the molecular formula is tight, so its physical properties are greater than resin and unsaturated polyester and other general thermosetting resins, strong adhesion.

In the epoxy resin fixing system, there are polar compounds such as epoxy group, hydroxyl group and ether bond, amine bond and ester bond, which give the epoxy fixed material excellent adhesion to metal, wood and other polar substrates, and the fixed shrinkage rate is small. It is usually 1% to 2%. It is one of the categories with small fixed shrinkage in thermosetting resins.

The application standard of epoxy resin anticorrosive steel pipe is large, and according to the use of epoxy resin coating, it can be divided into: powder for spray painting in the pipeline, powder for spray painting outside the pipeline, powder for oil drilling, and powder for multi-layer structure anticorrosion

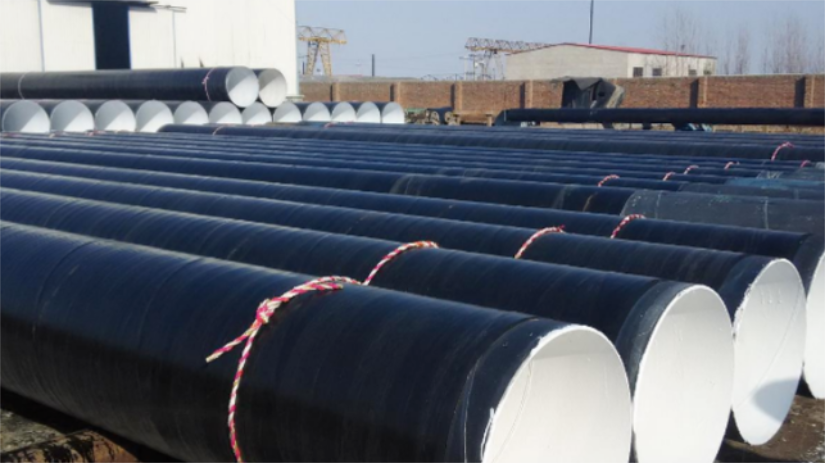

The multi-layer PE process produced by coating the double-layer fused steel pipe with epoxy resin and coiling or covering with adhesive is the currently widely used anti-corrosion process of the steel pipe at home and abroad, and also the current domestic west-east gas transmission and oil oil transmission, power supply, water supply and drainage of the pipeline anti-corrosion process.

Nowadays, most of them are using anti-corrosion epoxy resin coatings, and the application standard is large, which has long been spread across all regions of the world, from the land to the deep sea, from the plains to the slopes, rivers, natural lakes, from the Siberian steppe to the African desert, from the American continent to the Gulf of the Middle East, which has the use case of fused epoxy resin.

Advantages of epoxy coal anticorrosive steel pipe

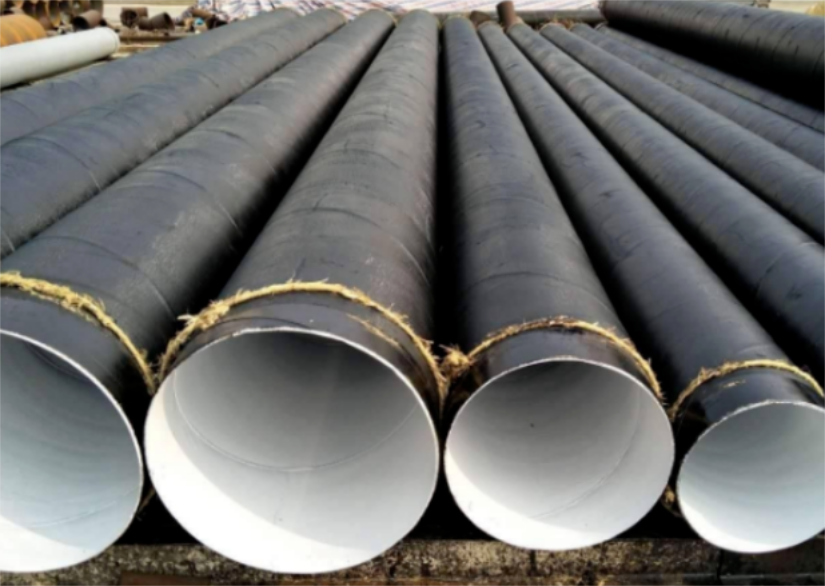

Used for pipeline anticorrosion of underground steel oil pipelines, water pipelines, sewage pipelines, etc. With the development of science and technology, the technology of various organic and inorganic high-efficiency anticorrosive coatings is more and more extensive, and is more widely used in pipeline anticorrosive construction.

Various anti-corrosion techniques have been gradually improved. When using epoxy coal tar coatings, pay attention to changes in climate and temperature. It does not apply to rain, fog, snow or buildings with relative humidity greater than 80%.

High-quality anti-corrosion coating is not easy to peel off, and the surface is very greasy. The combination with glass cloth is tight, and the bonding effect is good. After completely drying, hands will not feel rough, and there will be no strong pungent odor.

Surface treatment of epoxy coal asphalt asphalt anticorrosive steel pipe: Surface treatment is the first level of anticorrosive work, its quality directly affects the quality of anticorrosive construction, in the construction process should be serious, strict requirements.