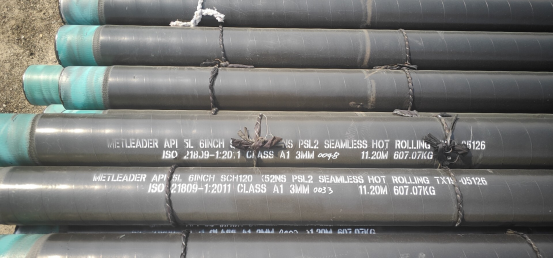

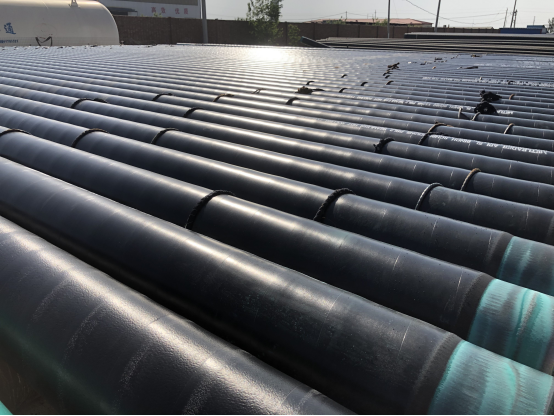

Line pipe with 3PE/3LPE coating

The brief introduction about line pipe with 3PE/3LPE coating.

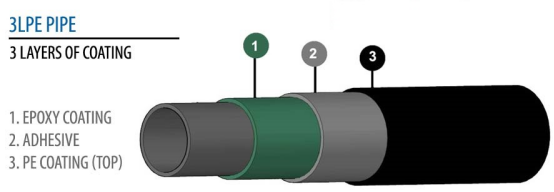

Line pipe with 3PE/3LPE coating is a kind of high-level anti-corrosive steel pipe. It consists of steel pipe + primer layer + adhesive layer + PE layer anti-corrosive structure. It has high corrosion resistance, high wear resistance and the normal service life is more than 30 years. This kind of pipe has these advantages the main reason is that its good quality anti-corrosive coating.

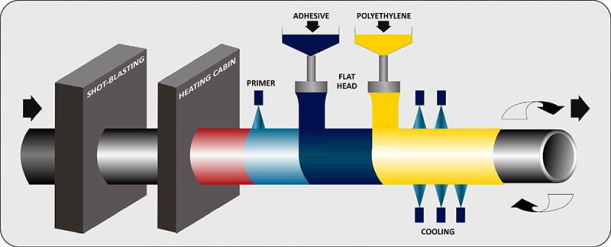

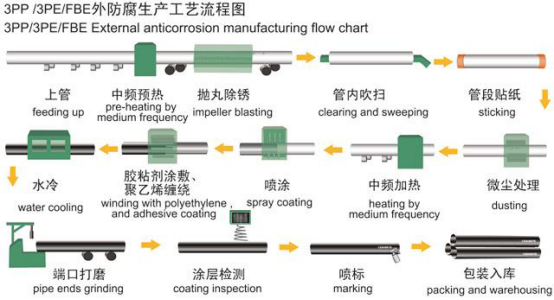

What is the production processing of line pipe with 3PE coating?

The processing method of 3PE anti-corrosive steel pipe is generally divided into winding type and round die cladding type. The second method is the most commonly used for line pipe which has the request for 3PE/3LPE coating.

Please see the below simple show on the picture.

Following content is the exact expression about the production processing.

The first step: visual inspection for steel pipe

Before starting the production, all line pipes should be inspected if there are defects such as severe mechanical damage, cold-lap, breaks, pits etc. The unqualified pipes should be marked and can’t be used.

The second step: rust cleaning

Rust cleaning of the surfaces of steel pipes is a very important chain, all pipes must be done rust cleaning through shot blasting derusting machine. The derusting grade should be reached to level Sa2.5. The rust, oil contamination, oxide skin and other dirts were all cleared away after this step. And for the line pipes which have defects must be repaired or eliminated.

The third step: dust treatment of the surface of steel pipe

After rust cleaning and before epoxy powder coating, dust treatment of the surface of steel pipe must be done. And the following step of epoxy powder coating should be proceed within 4 hours, otherwise the steel pipes will rust back.

The forth step: preheating of steel pipes

The temperature of reheating must meet the requested temperature of epoxy powder coating but not more than 275℃.

The fifth step: epoxy powder coating, adhesive coating and PE coating

Epoxy powder coating can be implemented through hot roller coating or hot spraying. Adhesive coating must be carried out during the gelling of epoxy powder. Lateral winding process is adopted for the winding of polyethylene strip. The polyethylene in the lap part and the polyethylene on both sides of the weld shall be fully rolled and compaction shall be ensured, and the surface of polyethylene layer shall be prevented from being crushed.

The sixth step: circulating water cooling

After finishing the production of anti-corrosive coating, the anti-corrosion layer should be cooled and shaped with circulating water.

The seven step: reserved length of bare pipe and pipe end grinding

After the anti-corrosion layer of the steel pipe is cooled and formed, the reserved length of the pipe end is 100-120mm according to the regulations. The bevel end angle of PE coating would be not more than 30 degree and the epoxy powder coating not more than 20mm can be retained outside the polyethylene end.

The thickness of each layer:

3PE coating line pipe is short for “three layers structure polyethylene anticorrosion coating line pipe”. There are three layers in this pipe coating structure:

The first one: Epoxy layer (Thickness > 100um)

The second one: Adhesive layer (Thickness: 170um~250um)

The third one: Polyethylene layer (Thickness: 1.8~3.7mm).

If the customer has special request for the coating thickness, Metleader can provide customized service.