Carbon steel pipe elbow

What's carbon steel pipe elbow?

What grade is carbon steel elbow material?

What are the different types of steel elbows?

Carbon steel elbow specification

Different degree of steel pipe elbow fittings

What's carbon steel pipe elbow?

Carbon steel elbows are divided into butt welding elbows and socket elbows. Elbows are mainly used at the turns of pipeline links to change the direction of the pipeline. Our factory mainly produces seamless and straight-seam industrial elbows. In the field of industrial piping, carbon steel pipe elbows play a vital role in ensuring the seamless flow of fluids or gases, and are mainly used in oil, gas and water treatment plants.

Standard of the carbon steel elbow fittings

The elbows produced by our factory are produced in strict accordance with ASME and ASTM standards. These standards were developed to maintain a high level of reliability, functionality and compatibility between elbow fittings.

ASME① and ASTM standards:

The American Society of Mechanical Engineers (ASME) and the American Society for Testing and Materials (ASTM) are globally recognized organizations that develop industry specifications and technical standards for the manufacture of elbows and other pipe fittings. ASME B16.9, "Factory Made Forged Steel Butt Weld Fittings," is a widely accepted standard that defines dimensions and tolerances for elbows and other fittings. ASTM A234, "Standard Specification for Medium and High Temperature Forged Carbon and Alloy Steel Pipe Fittings," provides guidance on materials, design, and testing of elbows.

| Standard | Specification |

| ASTM A234 | Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Moderate and High Temperature Service |

| ASTM A420 | Standard Specification for Piping Fittings of Wrought Carbon Steel and Alloy Steel for Low-Temperature Service |

| ASTM A234 WPB | ASTM A234 is Standard Specification for steel pipe fittings includes carbon and alloy steel material for moderate and high temperature services. WPB is one of the steel grade in this standard |

| ASME B16.9 | ASME B16.9 Standard covers overall dimensions, tolerances,ratings, testing, and markings for factory-made wrought buttwelding fittings in sizes NPS 1⁄2 through NPS 48 (DN 15 through DN 1200). |

| ASME B16.28 | ASME B16.28 Standard covers ratings, overall dimensions, testing, tolerances, and markings for wrought carbon and alloy steel buttwelding short radius elbows and returns. |

| MSS SP-97 | MSS SP-97 Standard Practice covers essential dimensions, finish, tolerances, testing, marking, material, and minimum strength requirements for 90 degree integrally reinforced forged branch outlet fittings of buttwelding, socket welding, and threaded types. |

| ASTM A403 | Standard Specification for Wrought Austenitic Stainless Steel Piping Fittings. |

AWWA: American Water Works Association

AWWA About – Established in 1881, the American Water Works Association is the largest nonprofit, scientific and educational association dedicated to managing and treating water, the world’s most important resource.

- AWWA C110 – Ductile-Iron and Gray-Iron Fittings, 3 Inch Through 48 Inch (75 mm Through 1200 mm), for Water and Other Liquids

- AWWA C208 – Dimensions for Fabricated Steel Water Pipe Fittings

ANSI: The American National Standards Institute

ANSI is a private, non-profit organization. Its main function is to administer and coordinate the U.S. voluntary standardization and conformity assessment system. It provides a forum for development of American national standards. ANSI assigns “schedule numbers”. These numbers classify wall thicknesses for different pressure uses.

JIS: Japanese Industrial Standards

This is the Japanese industrial standards or the standards used for industrial activities in Japan for pipe, tube and fittings and published through Japanese Standards Associations.

What grade is carbon steel elbow material?

10#, 20#, A3, Q235A, 20g, Q345B, 20G, 16Mn, ASTM A234, ASTM A105, st37 ASTM A403 and so on.

| Material | Steel pipe | Elbow fitting |

| Carbon Steel | A106 Gr A | A234 Gr WPA |

| A106 Gr B | A234 Gr WPB | |

| A106 Gr C | A234 Gr WPC | |

| Carbon steel, alloy, high-temp | A335 Gr P1 | A234 Gr WP1 |

| A335 Gr P11 | A234 Gr WP11 | |

| A335 Gr P12 | A234 Gr WP12 | |

| A335 Gr P22 | A234 Gr WP22 | |

| A335 Gr P5 | A234 Gr WP5 | |

| A335 Gr P9 | A234 Gr WP9 | |

| Carbon steel alloy low-temp | A333 Gr 6 | A420 Gr WPL6 |

| A333 Gr 3 | A420 Gr WPL3 |

What are the different types of steel elbows?

According to the production process:

Elbows are divided into butt welded elbows and seamless elbows.

The seamless steel elbow are made from a solid steel billet, which is heated and molded into a curved shape. The absence of seams in seamless elbows ensures a smooth flow of fluids, minimizing pressure drop and potential leakages. Seamless elbows are known for their structural integrity and durability, making them suitable for high-pressure and high-temperature applications.

The butt welded pipe elbows are made by joining two or more steel pieces together using various welding techniques. Welded elbows are generally more cost-effective than seamless elbows, making them a popular choice for low-pressure and low-temperature applications. However, the presence of welding seams can potentially create weak points in the structure, making them unsuitable for applications with high pressure or vibration.

According to the bending angle

The steel pipe elbow has 180 degree ,90 degree, 45 degree and 30 deg pipe elbow. We also can made another degree elbow fittings. If you have the Production drawings.It also has long radius elbow and shout radius elbow

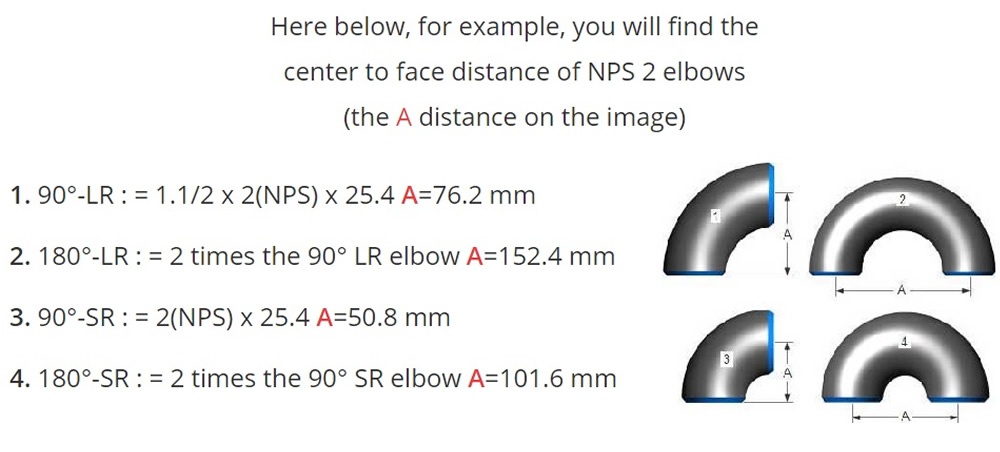

Elbows are divided into two groups, which define the distance at which flowing fluid changes direction; the centerline from one end to the other. This is called the "center-to-face" distance and is equivalent to the radius of the elbow's bend.

If the radius is the same as the pipe diameter (center to face dimension is 1.0 If the radius is larger than the pipe diameter (the center-to-face dimension is 1.5 times the diameter), we call it a long radius elbow (LR elbow) and is used for high pressure and high flow pipes.

The role of long radius elbow and short radius elbow in pipe connection

Long Radius Elbows:

Long-radius elbows, also known as LR elbows, are characterized by a larger centerline radius compared to short radius elbows. These elbows are designed to gradually change the direction of the fluid flow, offering enhanced flow characteristics. Due to their larger radius, long radius elbows exert less pressure drop, minimizing the chances of turbulence and erosion within the piping system. Consequently, they are highly suitable for low-pressure applications that require smooth flow transitions and minimal resistance, such as in HVAC systems and water supply pipelines.

One of the primary advantages of long radius elbows is their ability to minimize pressure drop. When the flow of a fluid needs to maintain a constant velocity, ensuring efficient performance, such as in the case of a pump system, using long radius elbows is preferable. The smoother flow transition offered by long radius elbows allows for optimal energy conservation and reduced wear on the pipes.

Short Radius Elbows:

Short radius elbows, also referred to as SR elbows, have a smaller radius compared to long radius elbows. This type of elbow causes a more abrupt change in direction and is often utilized in high-pressure applications where space constraints may limit the use of long radius elbows. Short radius elbows require less space between pipe fittings, making them a feasible option for tight or confined areas in manufacturing plants or refinery processes. Additionally, the use of short radius elbows reduces the cost of materials and installation due to the reduced physical dimensions.

Despite their cost-effectiveness and space-saving advantages, it is essential to consider the potential drawbacks associated with short radius elbows. As short radius elbows lead to more turbulence and increased pressure drop, they can be unsuitable for applications that require smooth flow transitions or involve conveying abrasive fluids. The higher pressure drop can cause erosion and wear on the elbows and pipes, leading to reduced efficiency and increased maintenance requirements. Therefore, careful evaluation of the application's specific requirements is vital before opting for short radius elbows in pipe connections.

Carbon steel elbow specification

| Nominal Pipe Size | Outside Diameter O.D | Long O | long K | Short O | Short K | STD T | SCH40 T | X-S T | SCH80 T | SCH160 T | XX-S T |

| 1/2 | 0.840 | 3.00 | 1.88 | - | - | 0.109 | 0.109 | 0.147 | 0.147 | 0.188 | 0.294 |

| 3/4 | 1.050 | 3.00 | 2.00 | - | - | 0.113 | 0.113 | 0.154 | 0.154 | 0.219 | 0.308 |

| 1 | 1.315 | 3.00 | 2.19 | 2.00 | 1.62 | 0.133 | 0.133 | 0.179 | 0.179 | 0.250 | 0.358 |

| 1-1/4 | 1.660 | 3.75 | 2.75 | 2.50 | 2.06 | 0.140 | 0.140 | 0.191 | 0.191 | 0.250 | 0.382 |

| 1-1/2 | 1.900 | 4.50 | 3.25 | 3.00 | 2.44 | 0.145 | 0.145 | 0.200 | 0.200 | 0.281 | 0.400 |

| 2 | 2.375 | 6.00 | 4.19 | 4.00 | 3.19 | 0.154 | 0.154 | 0.218 | 0.218 | 0.344 | 0.436 |

| 2-1/2 | 2.875 | 7.50 | 5.19 | 5.00 | 3.94 | 0.203 | 0.203 | 0.276 | 0.276 | 0.375 | 0.552 |

| 3 | 3.500 | 9.00 | 6.25 | 6.00 | 4.75 | 0.216 | 0.216 | 0.300 | 0.300 | 0.438 | 0.600 |

| 3-1/2 | 4.000 | 10.50 | 7.25 | 7.00 | 5.50 | 0.226 | 0.226 | 0.318 | 0.318 | - | - |

| 4 | 4.500 | 12.00 | 8.25 | 8.00 | 6.25 | 0.237 | 0.237 | 0.337 | 0.337 | 0.531 | 0.674 |

| 5 | 5.563 | 15.00 | 10.31 | 10.00 | 7.75 | 0.258 | 0.258 | 0.375 | 0.375 | 0.625 | 0.750 |

| 6 | 6.625 | 18.00 | 12.31 | 12.00 | 9.31 | 0.280 | 0.280 | 0.432 | 0.432 | 0.719 | 0.864 |

| 8 | 8.625 | 24.00 | 16.31 | 16.00 | 12.31 | 0.322 | 0.322 | 0.500 | 0.500 | 0.906 | 0.875 |

| 10 | 10.750 | 30.00 | 20.38 | 20.00 | 15.38 | 0.365 | 0.365 | 0.500 | *0.594 | 1.125 | 1.000 |

| 12 | 12.750 | 36.00 | 24.38 | 24.00 | 18.38 | 0.375 | *0.406 | 0.500 | *0.688 | 1.312 | 1.000 |

| 14 | 14.000 | 42.00 | 28.00 | 28.00 | 21.00 | 0.375 | *0.438 | 0.500 | *0.750 | 1.406 | - |

| 16 | 16.000 | 48.00 | 32.00 | 32.00 | 24.00 | 0.375 | *0.500 | 0.500 | *0.844 | 1.594 | - |

| 18 | 18.000 | 54.00 | 36.00 | 36.00 | 27.00 | 0.375 | *0.562 | 0.500 | *0.938 | 1.781 | - |

| 20 | 20.000 | 60.00 | 40.00 | 40.00 | 30.00 | 0.375 | *0.594 | 0.500 | *1.031 | 1.969 | - |

| 22 | 22.000 | 66.00 | 44.00 | 44.00 | 33.00 | 0.375 | - | 0.500 | *1.125 | 2.125 | - |

| 24 | 24.000 | 72.00 | 48.00 | 48.00 | 36.00 | 0.375 | *0.688 | 0.500 | *1.219 | 2.344 | - |

Please refer to the specific production standards

①https://www.asme.org/codes-standards/about-standards