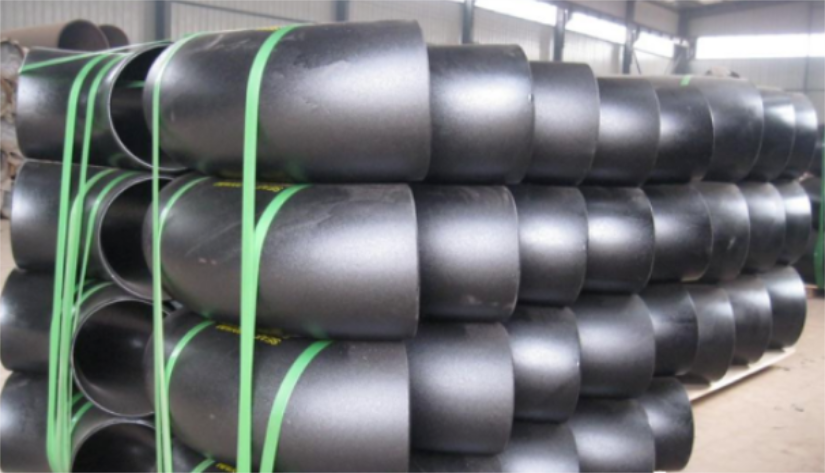

Carbon steel butt welding elbow construction matters

Large carbon steel butt welding elbows are usually produced according to detailed project standards or detailed drawings, not only considering the standard of pipeline specifications

We must also consider the details of pipe transfer resistance, fluid viscosity, damage, etch, fluid transfer temperature, etc. Second, the manufacturer of large butt welded elbows will give you a detailed introduction to the matters that need to be paid attention to when assembling large butt welded elbows.

ay attention to elbow construction

After the assembly and construction of large carbon steel butt welding elbow is completed, it is necessary to carry out anti-rust or corrosion cleaning according to the real situation of the pipeline or environmental factors to prevent corrosion or corrosion of the elbow at the spot welding place, resulting in too short service life of the elbow.

To prevent changes in the processing process, the layer outside both sides of the elbow, tile with stainless steel curved plate and keel to carry out correction structure reinforcement, according to the traditional welding technology, to carry out argon-filled spot welding, considering the cost of spot welding and shrimp waist tube diameter is too large, argon filling difficulty is too large.

In combination with the above factors, the internal and external welding machines are selected for symmetrical spot welding at the same time, which not only solves the phenomenon of argon filling, but also has excellent formability. Argon spot welding technology is selected. Argon arc welding is used as the bottom layer.

Before the welding operation, brush chalk powder in the 90mm area before and after the spot welding to avoid splashing and sticking to the surface of the pipeline. Select a small current before the spot welding operation. Many layers, multiple paths, continuous spot welding.

In order to avoid corrosion caused by heating, spot welding current should not be too large, less than carbon steel electricity before and after 19%, the arc can not be too long, rapid cooling between layers, spot welding narrow.

Until the whole welding is completed, the welding spot and splash on the surface of the large butt welding elbow are polished, non-destructive testing is carried out on the prefabricated spot welding tile, and the internal and external spot welding surface is cleaned by pickling and passivation. The pickling elbow is transported to the assembly site to carry out the final field assembly work.

Analysis of wear factors of carbon steel butt welded elbow

The wear of carbon steel butt welded elbows has always been a factor affecting safety and production, and with the continuous development of science and technology, materials are constantly innovating.

Casting stone, casting steel, alloy, centrifugal casting composite ceramics and other materials have appeared. Among them, the imported equipment is characterized by high wear resistance, high hardness, high oxidation resistance, corrosion resistance, high and low temperature strength

Most of the use of this carbon steel elbow, it has become a widely used wear-resistant material, accounting for about 80% of the world's specialty ceramics market share