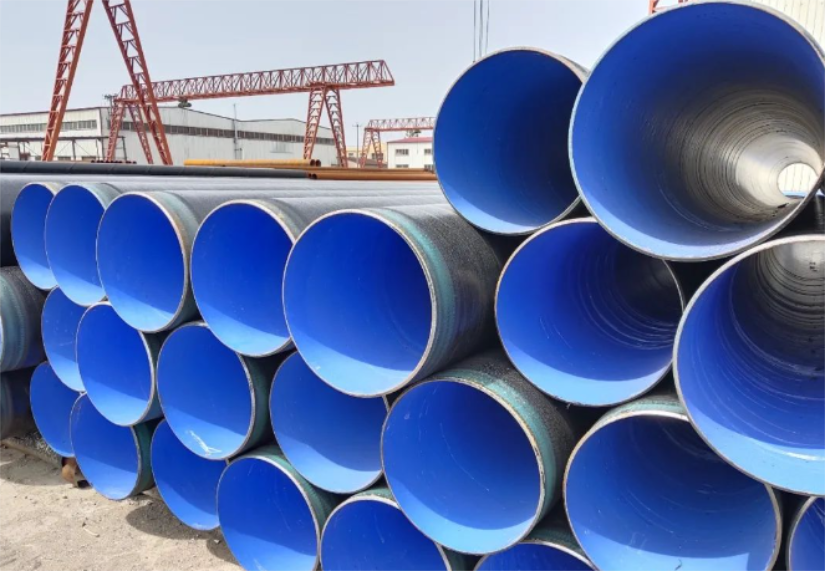

Method of cleaning tpep anticorrosive steel pipe

Pipe erosion is a common condition, so in order to prevent or reduce pipe erosion, it is necessary to take anti-corrosion measures

Under conventional conditions, the corrosion prevention method of steel pipe is mainly to coat additives, or the surface layer of the rust removed metal pipe is symmetrical and tightly coated with paint, or the inner cavity of the steel pipe is symmetrical and tightly coated with paint

Ways to enhance product longevity

Although some steel pipes have been cleaned against corrosion, this does not mean that they can be used for many years. In this case, what are the reasons for affecting the service life of tpep anti-corrosion steel pipes? Which reason is the key? How can we all fix this?

In order to increase the service life of tpep anti-corrosion steel pipe, the service life of tpep anti-corrosion steel pipe depends on the anti-corrosion method of the steel pipe to a large extent, so it is necessary to adopt excellent anti-corrosion coatings and anti-corrosion methods

In order to increase the service life of tpep anticorrosive steel pipe, it is necessary to start from the selection of anticorrosive paint, and the commonly used material of anticorrosive paint is mainly coal tar enamel paint, so that the pipeline can obtain stronger protection

However, these materials also have many defects, limiting their use area; As everyone knows, fortunately, with the progress of The Times, the existence of epoxy resin anti-corrosion melt powder coating has led to the rapid development of pipeline protection technology.

Dirt cleaning method

Reasonable anti-corrosion cleaning to start, to increase the use of tpep anti-corrosion steel pipe, in the steel pipe to carry out anti-corrosion cleaning, should pay attention to

Surface pretreatment, the metal surface inside the pressure steel pipe and on the surface is sprayed to remove rust, and construction is carried out in the corresponding sealed room

For a large number of rust removal pipes, rust remover or equipment can also be used to carry out equipment rust removal according to sandblasting and other methods, which can also improve production efficiency and reduce environmental pollution to people and air

Note the problems during use

The pipe body should be set on a good foundation, not placed on the dam fill, in addition, the concrete cushion should be set between the pipe body and the foundation, an expansion joint should be set every 10 to 20 meters along the pipe, and a water stop valve should be installed at the joint

The anti-seepage structure such as the clay core wall can be properly thickened, and then the impervious soil material of 1 to 2 meters thick is backfilled outside the pipeline, and a closed ring is installed every 10 to 20 meters outside the pipeline to increase the seepage diameter of the pipeline surface, which is also to prevent concentrated seepage.

If ordinary steel pipes are used in harsh environments, serious corrosion may occur, thereby reducing the service life of the steel pipes

At this time, the anticorrosive steel pipe is directly produced in this period, but there are many anticorrosive steel pipes, and the types of specifications are relatively common, so we need to master the way in the transportation process, so as not to cause damage due to insufficient transportation.