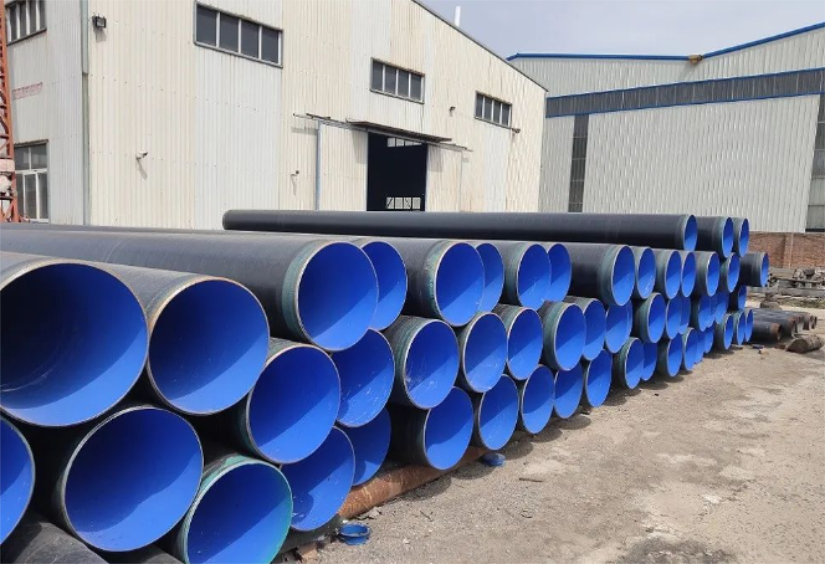

Production process of tpep anti-corrosion steel pipe

tpep anticorrosive steel pipe is determined by the anticorrosive process processing, the production of this kind of steel pipe can also prevent the reduction of chemical changes in the transport and use of the link resulting in corrosion, mainly has the characteristics of small pipeline roughness, internal smooth, good hydraulic characteristics

tpep anticorrosive steel pipe specification

Therefore, tpep anticorrosive steel pipes are usually used in various regional environments such as mine water supply and drainage, mine shotcrete, power plant process water waste, and return water transmission pipelines. Although tpep anti-corrosion steel pipes are commonly used in our lives, we should also pay attention to the following situations in the adoption process.

In use, the buried form of this kind of anticorrosive steel pipe should be an underground buried pipe, which is mainly composed of three aspects: water entry, pipe body and outlet section. The pipe body must be set on a better roadbed and can not be stored on the soil of the dam body

In addition, it is necessary to set fine stone concrete in the middle of the pipe body and the roadbed, set an expansion joint every 10 to 20 meters along the pipe, and assemble a water stop valve at the interface

It can also moderately thicken the anti-leakage structure such as the clay core wall, and then backfill the anti-leakage soil material of 1 to 2 meters thick to the outside of the pipe, and assemble an intercepting ring every 10 to 20 meters outside the pipe, so that you can increase the surface seepage diameter of the pipe, so as to avoid the accumulation of seepage

tpep anticorrosive steel pipe transportation

If the general steel pipe is used in a harsh regional environment, there will be obvious erosion, and then the service life of the steel pipe will be reduced, and the anticorrosive steel pipe will be directly born in this period.

However, because this kind of anticorrosive steel pipe is produced more, the size category selected is more common, so in the transport link we must grasp the form, can not be due to the transport is not in place and cause damage.

TPEP anticorrosive steel pipe manufacturing process

The steel pipe has excellent ductility, integrity and convenient construction operability, it is suitable for buried laying, can be used across the overhead, across the river and pipe roof construction, the inner wall and outer wall surface of the steel pipe and its accessories are coated with anti-corrosion coating, which is the most convenient and most commonly used protection method.

Steel-plastic composite pipes with internal and external protection are very cost-effective and combine the excellent properties of steel pipe and plastic pipe

It not only has the strength and stiffness of steel pipe, but also has the chemical resistance of plastic, no pollution, the inner wall is smooth and no scaling, and the fluid resistance is small, which can effectively prevent secondary pollution of water quality and has a significant effect on improving water quality

However, polyethylene is a thermoplastic material with flexibility and turbulence resistance. Because it is a non-polar molecule, it has poor adhesion to the steel pipe.

The group is easy to react with the steel pipe at a certain temperature, and the adhesion is strong, but because it is a thermosetting substance, it is not resistant to bumping. Therefore, the combination of the two materials is the best match for the current anti-corrosion industry