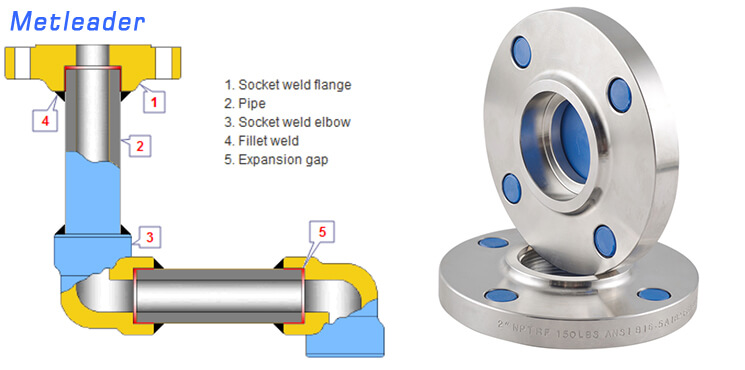

ANSI B16.5 socket weld flange

ANSI B16.5 socket weld flange is a flange that is inserted into the flange ring step at the end of the pipe and welded at the pipe end and the outside. There are two types of neck and no neck. The neck flange has good rigidity, small welding deformation and good sealing performance, and can be used for the pressure of 1.0~10.0MPa. The B-flange for containers is also a socket weld flange for applications requiring high sealing. When designing, the socket weld flange can be checked by integral flange.

Socket weld flange connection is an important connection method for pipeline construction. Flange connection is to fix two pipes, pipe fittings or equipment on a flange, and between the two flanges, with flange mats, bolted together to complete the connection. Some fittings and equipment have their own flanges and are also flanged. Socket weld flanges are threaded (wired) flanges and welded flanges. Low-pressure small-diameter wire-bonded flanges, high-pressure and low-pressure large diameters are all welded flanges. The thickness of the flanges of different pressures and the diameter and number of connecting bolts are different. Depending on the level of pressure, the flange pads are also available in different materials, from low pressure asbestos pads, high pressure asbestos pads to metal pads. The flange connection is easy to use and can withstand large pressures. In industrial piping, socket weld flange connections are widely used. The company specializes in the production and processing of socket welding flanges.

The socket weld flange is a flange that is bolted at one end to the other end of the steel pipe.

Sealing surface form: protruding surface (RF), concave and convex surface (MFM), grooved surface (TG), ring joint surface (RJ).

Applications: Boiler and pressure vessels, petroleum, chemical, shipbuilding, pharmaceutical, metallurgy, machinery, stamping elbow food and other industries.

Commonly used in pipelines with PN≤10.0MPa and DN≤40.

The socket weld flange is a flange that is bolted at one end to the other end of the steel pipe.

Connection method: flange nut, bolt connection.

Production process: professional overall forging, forging manufacturing, etc.

Processing methods: high-precision CNC lathe turning, general lathe finishing, argon arc welding and other processing.

Applications: Boiler and pressure vessels, petroleum, chemical, shipbuilding, pharmaceutical, metallurgy, machinery, food and other industries.

Sealing surface form: protruding surface (RF), concave and convex surface (MFM), grooved surface (TG), ring joint surface (RJ)

European nominal pressure: PN1.0MPa, PN1.6MPa, PN2.5MPa, PN4.0MPa, PN6.3MPa, PN10.0MPa diameter range: DN10-DN50

American nominal pressure: 150LB, 300LB, 600LB, 900LB, 1500LB

Path range: DN10-DN80

Material: carbon steel, stainless steel, alloy steel

Manufacturing standards: ANSI B16.5, GB/T9117.1-2000-GB/T9117.4-200, HG20592-2009 (PN series)\HG20615-2009 (Calss series)

The basic shape of the socket welding flange is the same as that of the neck flat welding flange. A hole is formed in the inner hole of the flange, the tube is inserted into the bearing hole and welded, and a weld seam is welded on the back side of the flange.

Due to the gap between the flange and the pipe, corrosion is sometimes caused, and if a weld is welded in the inside, the corrosion can be avoided. The socket welding flange welded on both sides is 50% larger than the flat flange and the static strength is the same.