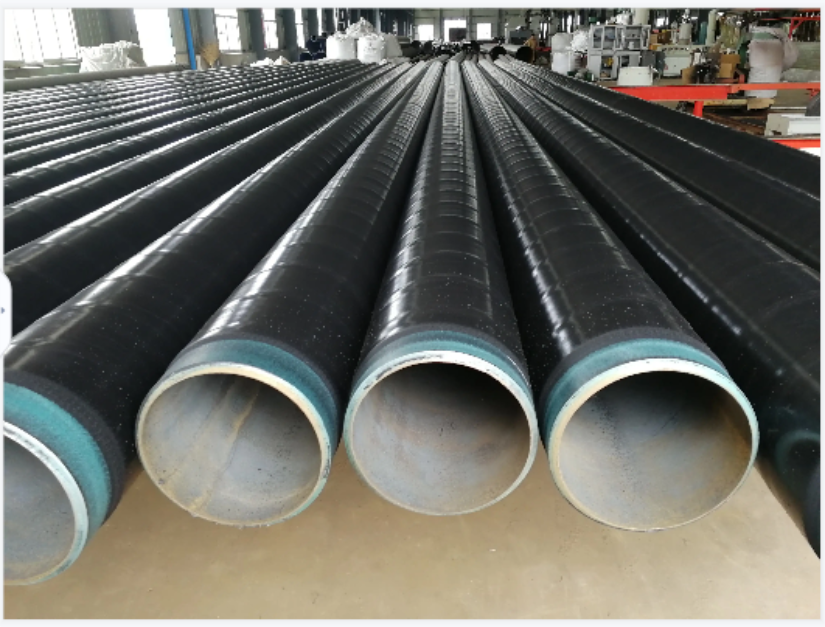

3pe anti-corrosion steel pipe quality factors

It has now become a corrosion resistant pipe that many industries will choose. It also has high sealing performance, long-term operation can save energy and cost to a greater extent, and can also play a protective effect on the pipeline.

At the same time, it also has a strong erosion resistance, and a long operating cycle. Even in a low temperature working environment, it can still maintain good corrosion resistance and shock response characteristics. In addition, it has very low water absorption and high mechanical strength

However, 3PE anti-corrosion steel pipe manufacturers often encounter bubbles in the welding process.

Especially for those large caliber pipes, such vesicles will not only affect the weld robustness of the pipe, but also cause the pipe to be rusted or cause leakage, and more seriously will weaken the physical mechanical strength and toughness of the weld.

Causes of small bubbles during processing

If the manufacturer of 3PE anti-corrosion steel pipe is based on the inmeticulous treatment of its windproof measures in the welding process, the molten pool is accidentally mixed with air.

This requires re-inspection and repair of the windproof device in the production and processing range to effectively ensure its normal operation to avoid gas flow such as drafts, and the weldment is not thoroughly treated

It will also cause some impurities to generate gas due to high heat when welding 3PE anti-corrosion steel pipes. In this regard, it is necessary to strengthen the cleaning of the weldment in advance, if the temperature of the molten pool is too low, the curing time is not reached.

This requires a moderate increase in the temperature of the molten pool, or an appropriate increase in the curing time, too long arc, or inappropriate protective gas flow of argon arc welding will weaken its protective effect.

In this regard, it is necessary to adjust the flow of protection gas and effectively ensure the purity of its air to meet the production and processing needs.

Factors affecting the quality of 3PE anti-corrosion steel pipe

Polyethylene will also undergo oxidation reaction, the pipeline is laid underground, the composition of underground soil sewage is complex, electrochemical corrosion and surfactants can accelerate the cracking of polyethylene under the effect of environmental stress.

Therefore, to ensure that the 3PE anti-corrosion steel pipe has a service life of several decades, the 3PE anti-corrosion material must have good light resistance and excellent mechanical strength, good environmental stress cracking resistance and excellent dielectric properties

According to the performance of the steel pipe preheat the steel pipe, and check whether its shape is good; According to the properties of the steel pipe, the coating is divided into three parts, and the surface of the steel pipe is cleaned by dust removal equipment to achieve the purpose of pretreatment

According to the actual production situation, constantly adjust the temperature to determine the treatment frequency of the coating (usually, the method of medium frequency heating is used to control the preheating device, in this process, the heat should be evenly sprayed on the surface of the steel pipe to reflect the efficiency