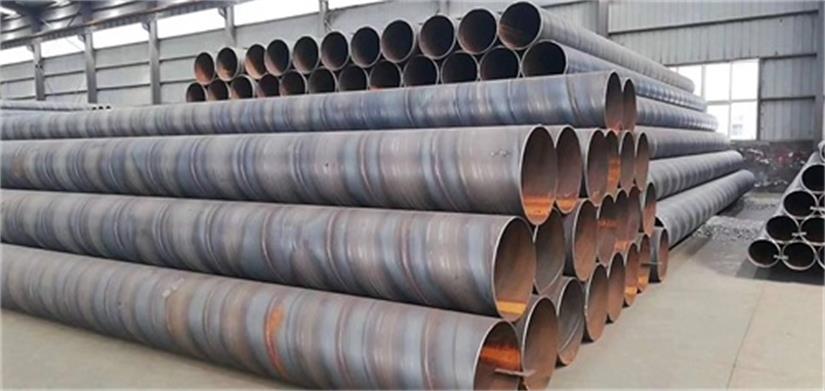

Spiral steel pipe quality safety

Spiral steel pipe in the application of safety factor supervision, spiral steel pipe packaging in the conventional transport, freight and storage links should prevent loose and damage, in some cases, buyers of spiral steel pipe packaging raw materials and packaging methods are special requirements, should be marked in the contract agreement

Manufacturer's management of safety

If it is not marked, the packaging materials and methods will be managed by the supplier, and the packaging materials should meet the relevant laws and regulations of our country

If you do not use packaging raw materials, the steel pipe produced should meet the expected use of some relevant enterprises to prevent material consumption and serious damage to the surrounding environment, then how to work safely on the spiral steel pipe, then by the spiral steel pipe manufacturers to explain how to regulate the safety factor

Some enterprises because of their own processing of the spiral pipe nozzle aiming in the displacement of the standard situation, in the quality management control should adopt the following preventive measures

As far as possible, the internal aiming device should be applied, and the construction measurement and trimming work should be done during assembly. Some parts can be analyzed and calibrated with copper hammer or copper plate hammer. When the displacement and deformation are carried out, the vacancy should be produced.

The safety of the spiral steel pipe work, before assembly, carefully carefully related to the facility is not able to operate regularly. When assembling, a specific person guides the operation in accordance with the relevant standards to prevent injuries

During the construction process, if it is necessary to use cushion blocks or sacks to pave the relevant pipelines, the cushion design must have a solid foundation to avoid accidents of pipeline rolling and hurting people; The spiral steel pipe is strictly prohibited from using frozen soil and stone as a cushion.

When manufacturers talk about the correct application of spiral steel pipe, it will immediately interfere with the service life of the steel pipe, so when assembling spiral steel pipe, it is necessary to meet the relevant standards to prevent serious interference with the subsequent application

Factors that determine the quality of spiral steel pipe

In general, the materials used to process spiral steel pipes are divided into many grades. Every grade is different and there is often a big difference in quality.

Therefore, to determine the quality, the manufacturer must present the corresponding material certificate, so as to know the level. This comparison shows that the quality is not the same.

When the spiral steel pipe is processed by different manufacturers, the introduced equipment and technology are different, and the quality and process of the factory will also have a very large gap. Therefore, in the process of comparison, it will be found that the quality of the process sold by the manufacturer is higher in the market, and the recognition of customers will also be significantly improved. In general, in this comparison to reasonably grasp the quality requirements, so as to judge the quality gap.

In the processing of spiral steel pipe, surface treatment is an essential process. In order to ensure that the quality of the steel pipe is strictly up to standard, the surface treatment needs to be more stringent at the factory to ensure the appearance quality and corrosion resistance, and the rust resistance and durability will be more and more prominent, so that the technical gap in all aspects is getting larger and larger, and the choice of customers will be different