Steel sleeve steel insulation pipe construction steps

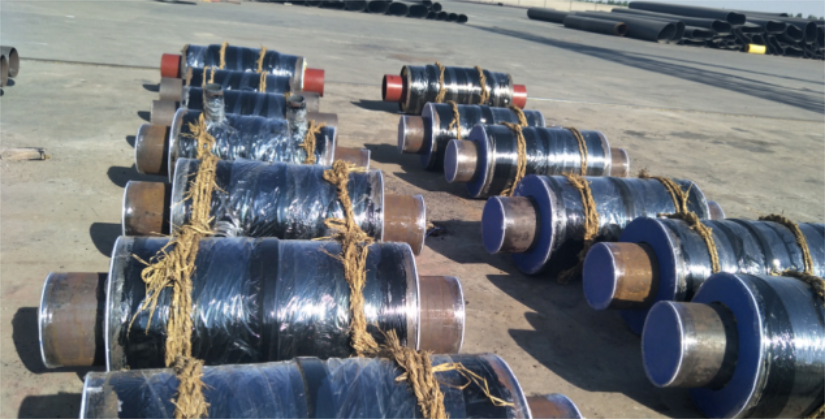

As we all know, steel jacket steel insulation steel pipe is slowly used in many industries and industries with its obvious unique features, it is composed of external pipes, thermal insulation pipes, thermal insulation layers and internal pipes, suitable for transmitting 2.3Mpa and steam or other media below 300 °C.

This product uses the pipe as the outer protective layer, so it is not suitable for destruction, saving time and effort in construction, and has a unique feature of long service time. And now the implementation of heating pipelines, so that the insulation pipeline industry has taken a new turn.

The concrete steps of construction

The method of direct burial is a major innovation in the construction industry. Steel sleeve steel insulation steel pipe is a transmission medium of the pipeline, is a combination of anti-corrosion coating and insulation cotton coated on the pipe

Can the steel sleeve insulation pipe be applied immediately after it is buried in the process? Nature is not allowed. After the completion of construction, it is necessary to carry out inspection before backfilling, and it can be applied only after the inspection has reached the standard. What kind of tests are there?

Steel sleeve steel insulation steel pipe compressive strength test, when assembling steel sleeve steel insulation steel pipe, set a stable pier to prevent the pipe network from moving out of a stable position and causing pipeline cracking. Therefore, after installation, it is necessary to increase the stress on the pipeline to see whether the pipe network will move the planned position in advance.

Steel sleeve steel insulation pipe pressure detection, the key to transfer high temperature steam, so the pipeline pressure test is key. After gently pressing, leave it for 30 minutes, observe the pressure change in the pipeline, and calculate the standard value, which is conducive to the routine maintenance of the pipeline.

Quality of construction

Argon arc welding should be used at the bottom of the weld and the trunk should also be checked. Grooves should then be filled to ensure that the outer shell of the insulation layer forms sufficient friction to prevent the inner steel pipe from contracting and thus damaging the internal insulation layer. When the pipe is heated, it should be heated slowly to prevent the smooth and separation of the pipe and the insulation layer.

The water in the insulation layer should be slowly discharged through the drain pipe to prevent a sudden explosion of the pipe when heating. After the water is drained, the working load value of the transport medium is slowly increased.

Before the steam passes through the steel sleeve steel insulation pipe, the condensate in the steam pipe network should be discharged, and the fluctuation range and frequency of the heat load should be gradually reduced.

The drainage device should also be checked to ensure that the condensate is unimpeded and to avoid the occurrence of water hammer, which can easily damage the compensator and pipe insulation structure.