What should we pay attention to cleaning 304 seamless elbows?

304 seamless elbow use time cycle is long, and if not well maintained, The 304 seamless elbow will become less and less beautiful and lose its previous brightness. So, in this case, how should seamless elbow clean up?

What should we pay attention to cleaning 304 seamless elbows?

Solvents and emulsions are used to clean elbows. Can remove oil, grease, dust, smooth agent, and similar organic matter in the use of these two types of cleaning agents to clean up the stains on the surface of ceramic elbow and ceramic composite elbow, but can not remove rust processing, oxide skin, welding, etc., on the surface of the steel. Therefore, only an auxiliary material, not a key preservative.

The 304 seamless elbows are treated with rust removal. The key is to use the wire brush to polish the steel surface, which can eliminate loose or warped oxide skin, rust, welding slag, etc., for the pickling of 304 seamless elbows, under normal circumstances, the use of chemical and electrolytic two kinds of methods for pickling.

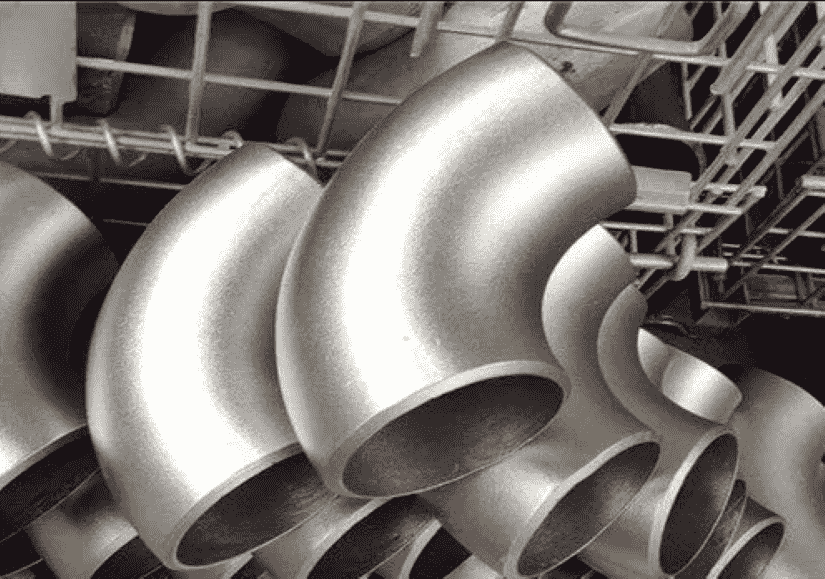

304 Seamless elbow production process

A pipe fitting used in the corner of the high-pressure pipeline is called seamless elbow, which accounts for a larger percentage of all pipe fittings used in the high-pressure pipeline system, about 80%. Usually, the seamless elbow is made of high-quality cast steel, stainless steel material, or alloy steel, which can make the seamless elbow bear high pressure in a variety of high-pressure pipes, and can bear the corrosion of the pipeline fluid, so the wall thickness of the seamless elbow is thicker than that of the ordinary elbow, or the high-pressure strength of the material is higher than that of the ordinary elbow.

The Stamping forming elbow is a forming production process that has long been used to produce seamless elbows. It has been replaced by hot push or other forming production processes in the production of common specifications of elbows. However, in some specifications of elbows, the wall thickness is too thick or too thin because the total quantity produced is small.

Before stamping, the tube blank is placed on the lower die, and the inner core and end die are loaded into the tube blank. The upper die moves downward and gradually presses, and the elbow is formed according to the constraint of the outer die and the supporting role of the inner die.