tpep anticorrosive steel pipe application and transportation

At this stage, corrosion is the key reason for the ineffectiveness of materials, and the transport link is a huge bottleneck problem. According to relevant materials, the economic losses caused by transportation each year account for about 5% of the total value of the national economy

With the continuous rapid progress of the economy, people's demand for energy is increasing, so we usually tpep anti-corrosion steel pipe application and delivery of attention point?

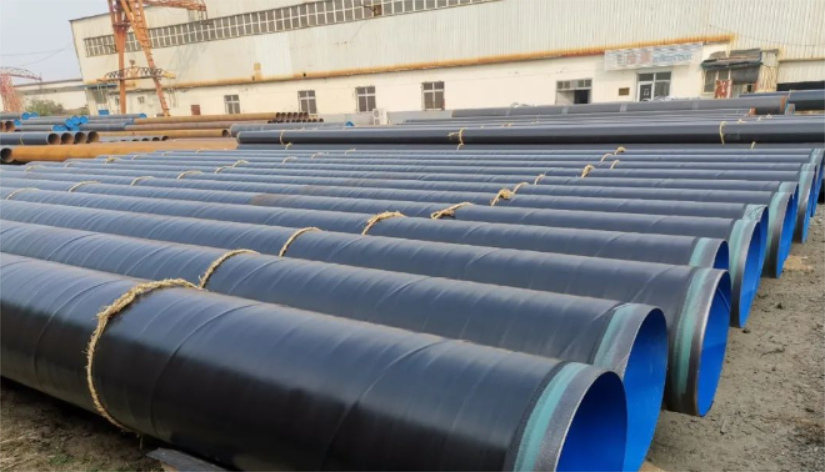

tpep anti-corrosion steel pipe is usually used

In view of the severe corrosion of the general steel pipe in the extreme regional environment, the service life of the steel pipe will be reduced, so the anticorrosive steel pipe came into being, and there are more manufacturers of anticorrosive steel pipes

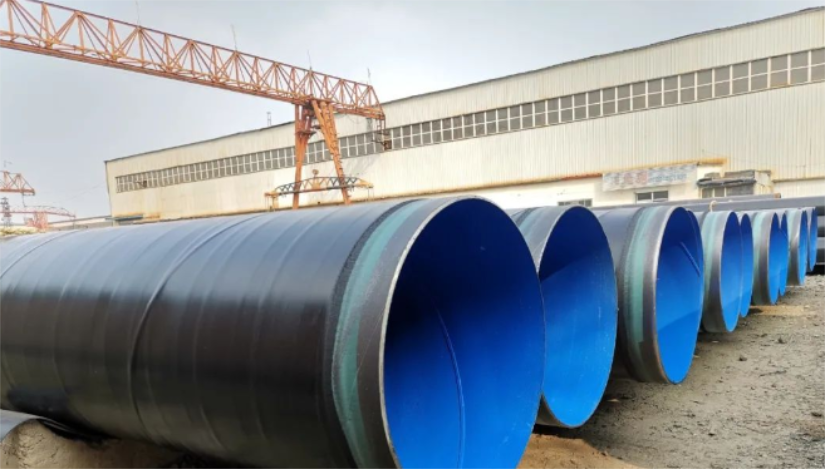

There are many specifications and specifications of tpep anti-corrosion steel pipes in the industry market, so it is necessary to grasp a reasonable form in the transportation process to prevent non-standard transportation from causing damage to it

Pay attention to handling tpep anticorrosive steel pipe

In the handling process, it is necessary to pay attention to not to carry out violent impact such as throwing and falling, so as to prevent damage to the product such as scratching; In the application and storage of tpep anti-corrosion steel pipes, attention should be paid to preventing oil stains and other chemical damage, and heat should also be prevented

tpep anticorrosive steel pipe can be stored indoors or outdoors, in the outdoor storage should be covered, to prevent wind and rain, storage tpep anticorrosive steel pipe, should pay attention to carry out smooth and orderly storage, accumulation degree should not exceed 1.5m, to prevent tpep anticorrosive steel pipe due to too much accumulation and collapse, resulting in tpep anticorrosive steel pipe scratching and damage.

The laying form of tpep anti-corrosion steel pipe is laid under the dam, which is composed of the water inlet, pipe body and outlet section. The pipe body should be set on a good foundation, and should not be set on the back of the dam foundation.

Concrete or masonry cushion layer should be set between the pipe body and the foundation, expansion joint should be set 10-20 meters apart along the pipe, water stop valve should be set at the interface, and anti-seepage structure such as clay core wall or inclined wall should be moderately thickened

The pipeline is the most important part of the water supply project, in the construction process, workers must ensure that the pipeline is sealed.

TPEP anticorrosive steel pipe is made of steel pipe as the base material, the outer wall adopts the thermal winding process of three-layer structure polyethylene anticorrosion, and the inner wall adopts the thermal spraying epoxy powder anticorrosion method

The powder is uniformly wound and coated on the surface of the pipe body after high temperature heating and melting, forming a film at one time, which greatly improves the corrosion resistance of the pipe and has a service life of up to 50 years.