Attention points in the transportation of spiral steel pipe

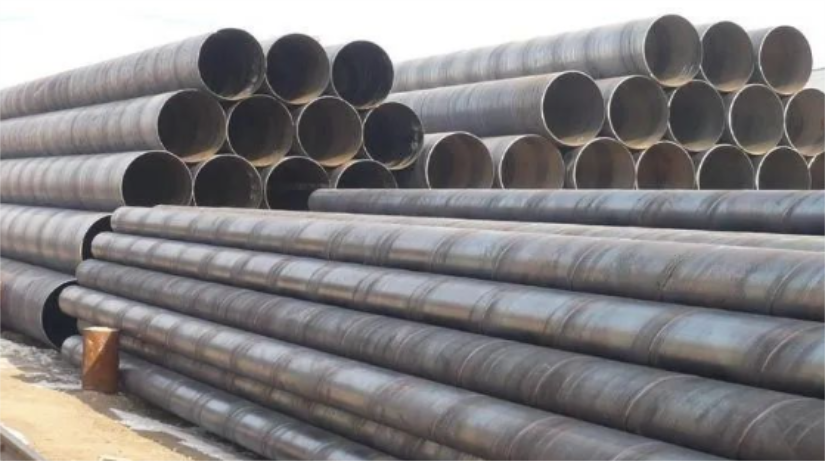

Nowadays, the use rate of spiral tube is getting higher and higher, and the total amount produced by spiral steel pipe manufacturers continues to rise. How can we prevent damage and friction during transportation? If it will lead to the appearance of spiral tube is not very good, so we should prevent it

Transportation of spiral steel pipe points

It can be divided into four to five kinds. When transporting spiral steel pipes, there should be prescribed packaging to avoid loose destruction in all normal disposal, storage and transportation links

If the customer specifies that the Spiral tube will not be destroyed, such as very uneven, it must be considered that the application of protective devices in the middle of the spiral steel pipe

Common specific includes rubber products, hemp rope, fiber cloth, plastic, tube cap, etc.; For thin wall Spiral tube, support points can also be added inside the pipe

A frame frame structure can also be added to the exterior of the pipeline; The metal composite material of the bracket and outer frame shall be the same as that of the Spiral tube

Spiral steel pipe packaging materials shall meet the regulations of relevant departments; If not, they should meet their estimated usefulness to prevent waste and lead to environmental pollution problems

In order to better avoid the Spiral tube scattered in the container, it can also be wrapped together or made external welding with protective supports; The state stipulates that the spiral steel pipe can also be packed loose. If the buyer has special requirements on the packaging products and packaging methods of the spiral steel pipe, it should be indicated in the agreement

Screw steel pipe after-sales service

Although the damaged spiral steel pipe has been restored to its original specification, style and matching characteristics after after-sales repair, the positioning accuracy will also interfere with the connection between the spiral tube

The deformation of mechanical parts can be divided into elastic deformation and plastic deformation, plastic deformation on the characteristics of metal parts and the use of greater interference

The concrete performance is the increase of compressive strength and hardness of metal materials, the decrease of plasticity and toughness and the occurrence of residual stress; In order to better reduce the interference of plastic deformation, according to these, we try to reduce the scope of damage

Above by the spiral tube manufacturers to briefly explain this knowledge, I believe that through reading, everyone has a general understanding of the website to get more contenthttps://metpipefitting.com/