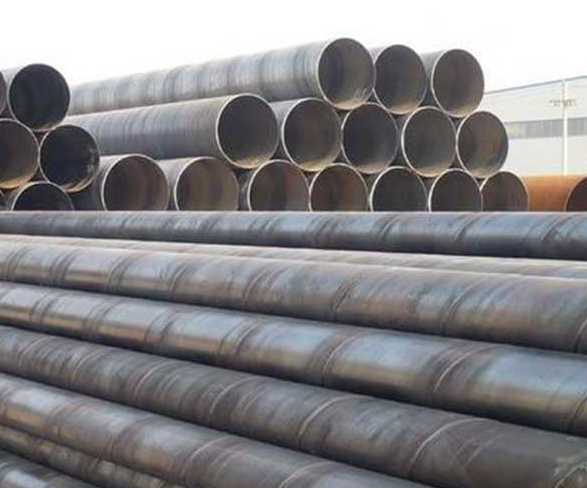

Storage and process of thick wall spiral welded pipe

For the storage of thick wall spiral welded pipe should be careful, in hot summer thick wall spiral welded pipe storage should be in accordance with the corresponding specifications, thick wall spiral welded pipe itself will be heated, if not stored, too much heat will cause the goods yard product warehouse personnel heat symptoms, so it is necessary to pay attention to this point

Storage of thick wall spiral welded pipe

It is necessary to store thick wall spiral welded pipe first, because the length of thick wall spiral welded pipe is basically determined to be 12 meters, so it is better to put, and thick wall spiral welded pipe decoration, according to the specification of a large, a small storage method

There is also a large specification of the first pile, next to the small specification, and then the large specification, and so on. This can also promote the loose and flexible hot gas, reduce the environmental temperature of the thick wall spiral welded pipe freight yard.

Hot weather has the dry season, thick wall spiral welded pipe is easier to rust, so thick wall spiral welded pipe stored to determine the pad wood or cement strip pad, to prevent water for a long time to soak, in order to prevent a lot of unnecessary losses.

Cement mortar anticorrosive steel pipe is made of cement and sand according to the inevitable proportion of mixing, the use of centrifuge to throw it to the inside of the steel pipe, in order to achieve the internal corrosion prevention function of the steel pipe.

Under normal circumstances, cement mortar corrosion prevention is used in the transport of sewage pipeline, because cement mortar corrosion resistance, so use this corrosion prevention method. At present, the old design institute still recommends this kind of anti-corrosion method, but according to many years of facts, this method is not only a waste of money, but also a short service life.

The interior of the cement mortar anticorrosive steel pipe has not gone through the sand blasting process, and the interior cannot reach the rust removal grade Sa2.5, which causes the adhesion of cement mortar to decrease, and the lifting back and forth in the construction process is easy to cause the cement to fall off. After the cement falls off, the sewage transport inside the pipe can be blocked, and the dirt can be silted for a long time, leading to the blocking of the steel pipe

How to operate thick wall spiral welded pipe without wrong edge

The sickle bend of steel strip is an important factor causing misalignment of steel pipe. In spiral welded pipe forming, the sickle bend of the steel belt will keep turning into the mold Angle, resulting in the change of weld clearance, resulting in seam opening, wrong edge and even edge matching.

When the weld residual height of steel head and tail butt welding is large, it is easy to cause large wrong edge if the punishment is not proper in the process of overforming.

Due to the poor shape and dimensional accuracy of the untrimmed steel lead and tail, it is easy to cause hard bending of the steel belt and cause wrong edge. Another important cause of misalignment is the unsecure state of steel strip edge.