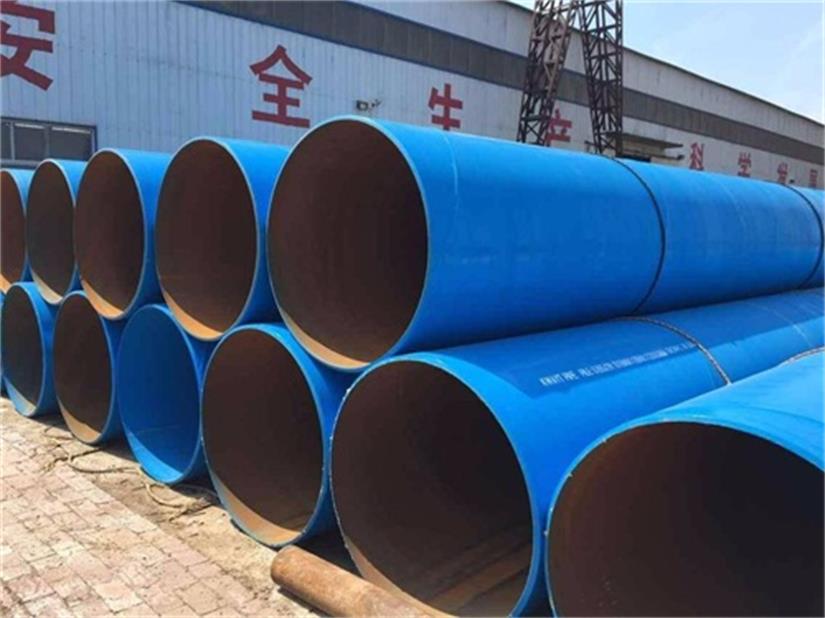

Rust removal and use of plastic coated composite steel pipe

Nowadays, the use of steel is very common, and we often see all kinds of steel in daily life, or it can be said that we will often use this kind of steel, precisely because of the wide range of use, in many areas will be used

Therefore, there are many materials on the steel market today, and the competitiveness is relatively large, and we have less understanding of the plastic coated composite pipe, about the application area of the plastic coated composite pipe and how to prevent it, next let us briefly introduce.

Rust removal of plastic coated composite steel pipe

The production process of this pipe is complicated and contains the high-tech information of the construction unit, so the plastic-coated composite pipe will be commonly used in some key project areas, and the special pipeline of west-east gas transmission is mostly plastic-coated composite steel pipe, and sometimes it is also used for Russian crude oil export trade.

In fact, this kind of plastic coated composite steel pipe in our daily production is also more repeated, if you observe more, you can find that the usual factory or family community use of water pipes and drainage pipes are more special, most of these are used in steel plastic composite pipes.

After rust removal is carried out on the surface of the plastic-coated composite steel pipe, 90% of the common rust on the surface is removed, and 5% of the residual rust exists, and the old paint on the oil tank can be shoveled off with an alloy steel shovel.

This type of oxide layer is usually thin, so that according to it, the natural brightness of the surface of the equal channel tee can be seen, so that the equal channel tee has the same appearance.

Brush the welding place with a tool, remove rust in the blind area of the parts such as the coated plastic steel pipe, and the adhesion between the coating and the matrix is the key criterion for evaluating the corrosion resistance of the coating

The stronger the adhesion, the better the corrosion resistance, the more the coating is used, and the oil, asphalt and other dirt on the surface of the plastic steel pipe are cleaned with acetone or other volatile substances. The surface of the coated steel pipe should be dry after cleaning, and there is no crude oil and dirt.

Plastic coated composite steel pipe use area

Water applications, if the use of a single seamless steel pipe, hot-dip galvanized seamless steel pipe, etc., so in the process of use will be very easy to be corroded, it is easy to leak or environmental pollution of water flow phenomenon.

And coated steel pipe is very environmental protection, can achieve safety without carcinogens, both corrosion resistance, and wear resistance durable, is a good choice.

Can be used in fire water supply system software. The surface of the general seamless steel pipe is very easy to get stains, so it is easy to block when used in emergency situations, delay emergency rescue and other cleaning, and the adverse effects can not be borne.

If the fire safety water supply equipment is applied with the advantages of heat resistance and not easy to accumulate scale, it can greatly ensure that the rescue is carried out, which can ensure the personal safety and capital safety to the greatest extent, and also reduce the cost of sewer maintenance and equipment maintenance of fire protection facilities