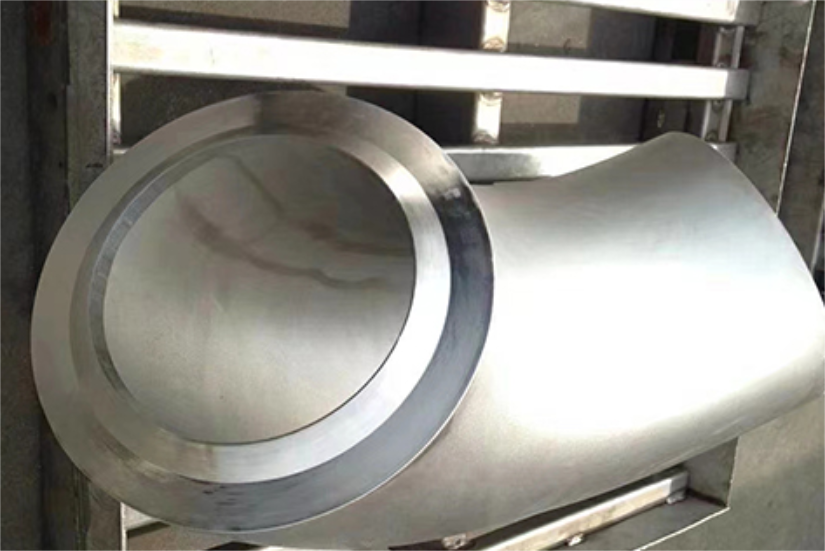

How to do stainless steel elbow rust removal

Stainless steel elbows occupy a large proportion in the pipeline, but the use of stainless steel elbows is too long, and rust is inevitable. Rust not only affects pipe corrosion, but also leads to leakage, causing serious problems. The economic loss is large, so the stainless steel elbow should pay attention to rust prevention.

Stainless steel elbow rust prevention method

Focusing on the corrosion protection of stainless steel elbows can also extend the service life. As everyone knows, the corrosion prevention practices of stainless steel elbows in different regions are not the same.

In the south of our country, the air is humid, which is also chemical hydrogen evolution corrosion. Water is one of the things that makes iron easy to rust, only when oxygen is dissolved in the air.

In water, oxygen reacts with iron in the water environment, creating something called iron oxide, which is rust. Rust is a reddish brown substance. It's not as hard as iron. It's easier to fall. When a piece of iron is completely rusted, its volume can expand by eight times.

If the rust is not removed, the spongy rust is very easy to absorb water, which will accelerate the corrosion of stainless steel elbows. Therefore, in the southern region of the country, in view of the influence of humidity and temperature, the corrosion protection of stainless steel elbows must use heavy corrosion protection.

Stainless steel elbow anticorrosion, if the pipe corrosion is too thick, should first use a hand hammer to knock down the rust layer. When the rust layer is not thick, wipe the surface with a wire brush, steel wire cloth or coarse abrasive cloth until the primary color of the pipeline is exposed, and then wipe with cotton yarn head. This method is only for scattered and scattered rust, and is not suitable for large areas.

Sand blasting is an advanced method of rust removal in chemical pipeline anticorrosion. This method can not only remove the rust layer, the old paint layer and other dirt on the surface of the steel pipe, but also generate small symmetrical impurities on the surface of the steel pipe.

This can increase the bonding force between the anti-corrosion layer and the metal pipe, improve the anti-corrosion effect and service life of the coating, and lay the foundation for the subsequent.

Stainless steel elbows buried in the ground are usually subjected to a chemical pickling process that removes rust and old coatings. However, it should be noted that although the chemical pickling process can clean the surface of the stainless steel elbow, its anchoring method is shallow and easy to pollute the environment.

Therefore, chemical cleaning is not recommended. Therefore, anti-corrosion stainless steel elbow should be born, it is not only not easy to rust, and firm beautiful and generous, very popular in the market.

The process indicators that affect the geometry of pipe fittings are

The material, thickness and outside diameter of the blank used for pushing, the material and style of the mandrel head, the heating temperature and its division and the advancing speed.

Different types of elements have different effects on pipe fittings, which should be used in accordance with the corresponding ways and methods, and the specific use value and role of pipe fittings in use.

Stainless steel elbow in the use of an important role and performance, in the use of the process to use it for maintenance and inspection, stainless steel elbow corrosion, usually manifested as stainless steel elbow wall softening, the occurrence of local dents and impurities.

For the reasons and methods of internal corrosion should be carried out in accordance with the way and principle, the more common corrosion detection methods that can be used now are leakage flux method and acoustic detection method.

The special wave detection method uses the pulse reflection principle of sound wave to detect the thickness of pipe wall after corrosion.