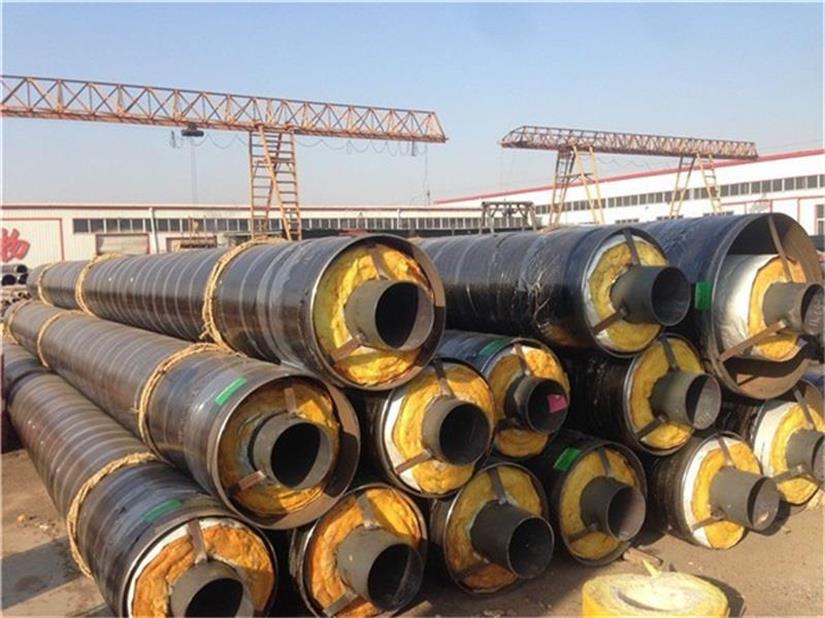

Steel sleeve steel composite insulation steel pipe knowledge

Steel jacket steel composite insulation steel pipe in the project, a practical and durable steel pipe, is used in the transport of materials, what are the general characteristics, what way to choose to carry out the installation, let's take a look

Steel sleeve steel composite insulation steel pipe installation steps

It is a type of underground pipeline, and the method of direct construction under the ground can be carried out without concrete, that is, the thermal expansion of the operating steel pipe is carried out in the outside pipe, which reduces the material cost and reduces the construction period

And ensure the safety factor of the heating pipeline, can be used more reliably in different temperature environments, especially for high temperature steam pipeline projects. The application temperature reaches 130℃-500℃. Pipe ports are generally sealed with polyethylene film or three-layer PE cold wrap to avoid moisture or water entering before installation or during construction.

The double-layer staggered binding of the insulation material effectively reduces the heat loss. In addition, preventive measures are adopted on the outer layer of the coat to avoid the occurrence of freezing of the steel pipe, and thus the temperature control of the anti-corrosion layer of the coat is guaranteed.

The double aluminum foil reflector is bundled with insulation material, which effectively reduces the heat loss and makes the steam pipeline more economical and efficient. The drainage system adopts closed mode, convenient layout, reasonable structure and reliable.

The steel pipe on the steel sleeve can not only immediately remove cold and wet air, but also serve as an alarm information pipe for normal operation. The thermal compensation of the pipeline is made of excellent bellows compensator, which is installed in the casing and made into direct burial mode, without setting observation well, convenient operation and tight construction period.

Suitable for the transport of 2.5MPa, 300℃ below the steam or other substances, the product with steel pipe as the outer protective layer, with high strength, not easy to destroy, simple construction and maintenance, long service life unique.

Steel sleeve steel insulation steel pipe can withstand the temperature

The first problem is the reliability of strict waterproof, in addition to have good mechanical strength, steel sleeve due to high strength welded connection, waterproof sealing performance reliability is very high. In addition, its high temperature resistance is unmatched by other external protective tubes.

The difficulty of waterproof and leak-resistant was successfully solved by using the characteristics of high strength and good sealing performance of the steel sleeve. The inner layer of the insulation material was patched by microporous calcium silicate at different seams on the inner steel pipe, and the gap was filled with high temperature and high elastic insulation material, which effectively reduced the heat loss.

The outer insulation is made of polyurethane insulation material, and the excellent insulation performance of polyurethane is used to control the surface temperature of the coat below 50 ° C, protect the anti-corrosion layer, and increase the overall life of the pipeline.