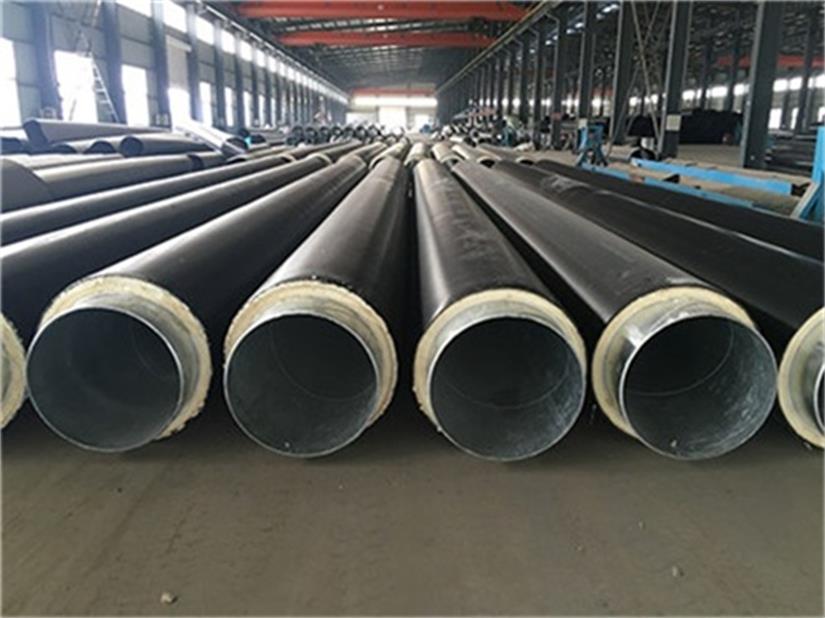

Application of steel jacket steel insulation pipe

At present, the biggest problem of the insulation pipe is the service life level, so this kind of service life is a larger binding factor

In the process of analysis from the level of this kind of service life, the advantages of this kind of material are more prominent, and the most common application is steel sleeve steel insulation steel pipe

Steel sleeve steel insulation steel pipe use period

Although this kind of material is very light in weight, its chemical properties are certainly relatively stable, which effectively ensures that it will not be affected in the application process, and the application of multi-layer design can make the deadline more strongly guaranteed.

The service life of this kind of steel jacket steel insulation pipe is now 25-45 years, so in the process of application in the industry, it can ensure that it will not get other levels of impact, which acid and base impact is a key level

Therefore, the corrosive effect of pH itself can reduce the life of its own material by a lot, but this type of material can achieve excellent results in pH resistance

Steel jacket steel insulation pipe itself in the design process, the selection of multi-layer design mode, from this type of design mode to get their own period of a stronger way

The advantage from its own life is that it can achieve excellent results, and the materials applied in the multi-layer design are completely different

From the material is not the same way inside can also show the absolute feeling, so the material level of the formal way is relatively different

In the process of the term of this kind of material, many complex substances are added to their materials, and the key significance is that they meet the demand of various industries from the term side, and then ensure that the material is better applied in the industry, and the scope of current use is still increasing

Steel sleeve steel insulation steel pipe coating anticorrosion

It is used to isolate the steel jacket steel metal pipe and soil to prevent the electrolyte from directly contacting the metal outer wall, so that the electrochemical reaction cannot occur, and the single anti-corrosion layer is difficult to meet the complex corrosion environment of the steel jacket insulated steel pipe, so the multi-layer anti-corrosion system is used

Its structure is: the bottom layer is a multi-purpose epoxy coating with a thickness of 100 microns; The middle layer is copolymer hot melt adhesive, the thickness is 180-250 m; The outer layer is polyethylene anti-corrosion layer, the thickness is 3.7mm; The system has been in use for more than 40 years