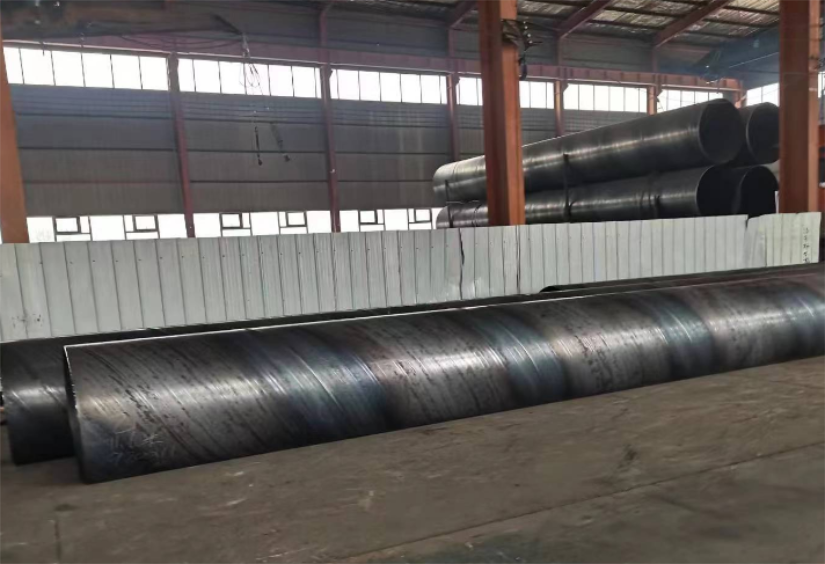

The treatment of spiral steel pipe surface and its quality

The spiral steel pipe is durable and practical, and has become the key signal of engineering construction, but the maintenance medium transported is one of the key materials. The spiral steel pipe is the outer wall anticorrosion construction of the steel oil pipeline, gas pipeline, water supply pipe and heating pipe

In order to better enhance the service life of the anti-corrosion spiral pipe, the manufacturer should carry out appropriate surface treatment, and the surface treatment of the spiral steel pipe is helpful to enhance its service life.

The surface treatment of anti-corrosion spiral pipe is introduced

First,To be sent to the surface of the anti-corrosion spiral steel pipe, this can solve the organic matter on the surface of the spiral steel pipe, but it can not solve the surface layer rust, oxide, welding, etc., so cleaning can only be used as an auxiliary way.

Second,Use wire brush, sandpaper and other equipment to polish the surface layer of anticorrosive spiral pipe, which can remove loose oxide, rust, welding slag and so on.

Third,The selection of organic chemical pickling process for pipeline corrosion protection can remove the oxide surface, rust and old coating, and can make the surface layer achieve the corresponding cleanliness and roughness.

Number four,According to the high-power motor to promote the high-speed operation of the spraying (throwing) shooting blade, so that the abrasive sand, steel balls, iron wire segments, minerals and other abrades in the centrifugal force function of the anti-corrosion steel pipe surface layer to carry out spraying (throwing) shooting cleaning, not only can completely eliminate rust, oxides and dirt, and anti-corrosion steel pipe in the abrasive strong impact and friction function, but also can achieve the required uniform roughness.

Anti-corrosion spiral steel pipe is good or bad

Enhanced grade anti-corrosion spiral control finished product appearance testing plan, enhanced grade anti-corrosion spiral pipe technology is introduced from abroad in the late 1990s professional anti-corrosion technology, its processing methods are usually divided into winding and circular mold coating type two categories, anti-corrosion spiral pipe from the appearance can be significantly identified.

Distinguish from the appearance, that is, detect in appearance. The appearance test of the butt weld is such a simple and common test method, which is a main information of quality inspection, mainly to find the shortcomings of the appearance of the weld and the error of the size.

It is generally observed by the naked eye, and the inspection is carried out by special tools such as standard templates, gauges and high-magnification glasses. If there are shortcomings on the surface of the weld, the internal structure of the weld is likely to have shortcomings, especially on the large-caliber anticorrosive spiral pipe.