Knowledge of anti-corrosion insulation steel pipe

We all know that the steel pipe can not be exposed to the sun, it will affect the use of the steel pipe, it will affect the service cycle of the steel pipe, so the storage of the steel pipe and understand the characteristics of the performance is still very important, today the anti-corrosion insulation steel pipe factory will take you to understand some knowledge of the anti-corrosion insulation steel pipe

Knowledge of anti-corrosion insulation steel pipe

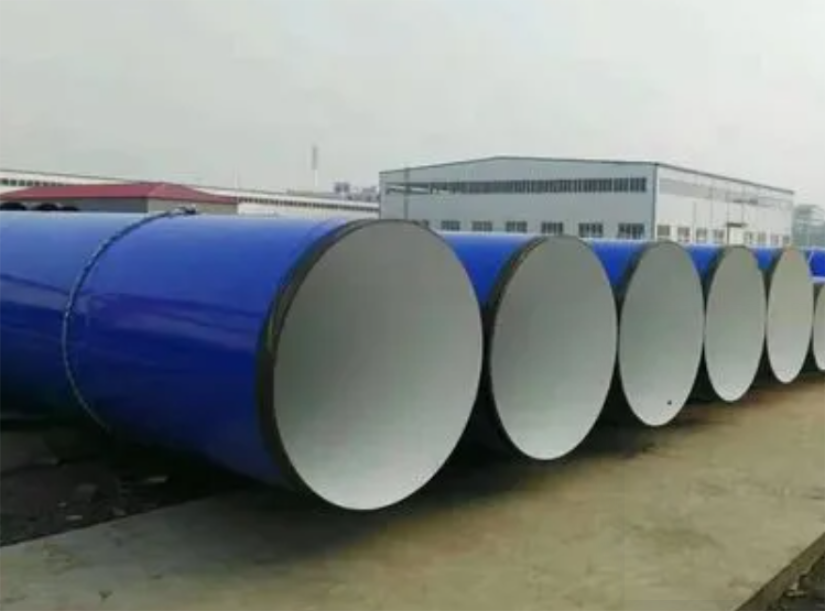

Although we all know its figure, but for some of the performance is still not very understanding, its insulation is better, it can be that the heat energy is not so volatile, it can operate for a long time, saving a lot of resources so as to reduce the cost of resources, it also has super waterproof and corrosion resistance under low temperature conditions, after reaching the qualified standard factory, It can be directly buried in the ground or water and other characteristics of anti-corrosion insulation steel pipe

Anticorrosion method of steel pipe

The inner and outer wall anti-corrosion coating, the anti-corrosion insulation body layer, the coating inside is to prevent the inner being eroded, reduce resistance, and improve the transportation volume, so the film coated in the inner is distributed in the anti-corrosion surface layer, so that the steel pipe and the corrosive substances are separated, which is one of the basic methods of anti-corrosion steel pipe

In recent years, the laying of pipelines in harsh regional environments such as polar regions and deep seas, and the heating and transportation of oil make the pipeline temperature rise, etc., which has pointed out a lot of regulations on coating characteristics.

Therefore, the anti-corrosion steel pipe coating is more and more used metal composite materials or composite structures. This material and structure should have electrical properties, physical properties, stable chemical properties and a wide range of temperature adaptation.

Insulation layer of steel pipe

The effect of insulation is not only related to the thickness of insulation, but also closely related to the density and quality of the insulation layer, which are specified in the national standards.

Should be specific problem specific analysis, reasonable design for different use of the environment, to avoid meaningless blind increase in thickness waste insulation material to increase operating costs.

Thermal insulation steel pipes have different processing types and methods, such as the use of high-density polyurethane, aluminum silicate wool, rock wool, ultra-fine glass wool as thermal insulation materials

High density polyethylene pipe, high strength glass steel pipe and spiral steel pipe are used as outer protective pipe. Different processing methods determine that the insulated steel pipe has different properties and functions, and the scope of use will also change.