Carbon steel socket elbow

What is carbon steel socket elbow?

Carbon steel socket elbow is a kind of high pressure pipe fitting which is made of round steel or steel ingot and then forming it by lathe machine. The material is carbon steel ASTM A105 and the standard is ASME B16.11.

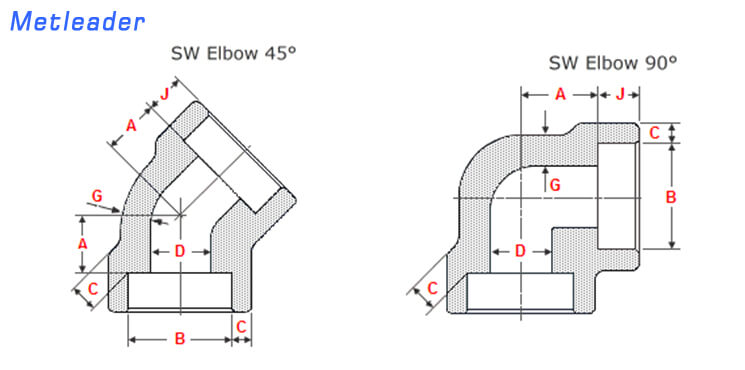

If dividing according to forming it including 45 degree and 90 degree socket elbows.

The size of carbon steel socket elbow generally includes DN6、DN8、DN10、DN15、DN20、DN25、DN32、DN40、DN50、DN65、DN80、DN100 according the standards.DN15 to DN50 are the most used widely. If order the size is over the dimension range, customized drawing processing is available.

The pressure of carbon steel socket elbow refers to 3000BL, 6000BL and 9000BL.

Some specifics of carbon steel socket elbow

1.They are used to transport flammable, toxic or expensive materials in pipelines, do not allow leakage, and 300 to 600 PSI of steam.

2.They work only with ASME pipes and have the same size range.

3.They are used in permanent areas where pipes work and are intended to provide good flow characteristics.

4.They are manufactured according to several ASTM standards and ASME B16.11.The B16.11 standard covers pressure and temperature ratings, dimensions, tolerances, marking and material requirements for forged carbon and alloy steels.The acceptable material forms are forgings, bars, and seamless pipes which meet the chemical, smelting practice and mechanical requirements of ASTM A105.

The advantages and disadvantages of carbon steel socket elbow.

The Advantages of carbon steel socket elbow:

1.Pipes do not need to be tilted for welding preparation.

2.Alignment does not require temporary positioning welding, as the joint is guaranteed to be correctly aligned in principle.

3.The weld metal cannot penetrate the hole in the pipe.

4.They can be used in place of threaded fittings, so the risk of leakage is much lower.

5.Radiography of fillet welds is not practical;Therefore, correct installation and welding are crucial.Fillet welds can be checked by surface inspection, magnetic particle (MP) or liquid penetration (PT) inspection.

6.Due to the lack of strict assembly requirements and the elimination of special processing of butt welding ends, the construction cost is lower than that of butt welding joints.

The Disadvantages of carbon steel socket elbow:

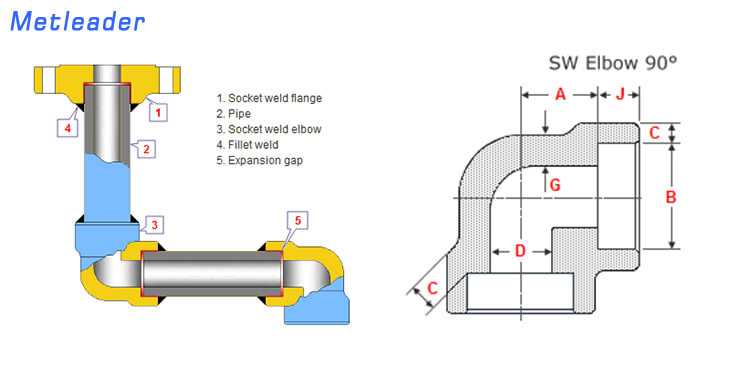

1.Welder shall ensure 1/16 "(1.6mm) clearance between pipe and socket shoulders.

ASME B31.1 segments.127.3 welding preparation (E) sleeve welding assembly:

When assembling the joint prior to welding, the pipe or pipe shall be inserted into the socket to the maximum depth, and then approximately 1/16 inch (1.6 mm) shall be removed from the contact between the end of the pipe and the socket shoulder.

2.Expansion gaps and internal cracks left in socket welding systems can promote corrosion and make them unsuitable for corrosive or radioactive applications where solid accumulation at the joints may cause operational or maintenance problems.Butt welding is usually required in all pipe dimensions and is fully welded into the pipe.

3.For ultra-high static pressure (UHP) in the food industry, socket welds are unacceptable because they do not allow complete penetration and leave very difficult to clean overlaps and cracks, resulting in virtual leaks.

The dimensions of carbon steel socket elbow.

The pressure of carbon steel socket elbow refers to 3000BL, 6000BL and 9000BL. But 3000BL and 6000BL are more popular. Please see the dimension data about carbon steel socket elbow 45 degree and 90 degree 3000BL.

| NPS | Socket Bore |

Depth Socket |

Bore DIA |

Socket WT |

Body WT |

| B | J | D | C | G | |

| 1/2 | 21.95 21.70 |

10 | 16.6 15 |

4.65 4.10 |

3.75 |

| 3/4 | 27.30 27.05 |

13 | 21.7 20.2 |

4.90 4.25 |

3.90 |

| 1 | 34.05 33.80 |

13 | 27.4 25.9 |

5.70 5.00 |

4.55 |

| 1¼ | 42.80 42.55 |

13 | 35.8 34.3 |

6.05 5.30 |

4.85 |

| 1½ | 48.90 48.65 |

13 | 41.7 40.1 |

6.35 5.55 |

5.10 |

| 2 | 61.35 61.10 |

16 | 53.5 51.7 |

6.95 6.05 |

5.55 |

| 2½ | 74.20 73.80 |

16 | 64.2 61.2 |

8.75 7.65 |

7.00 |

| 3 | 90.15 89.80 |

16 | 79.5 46.4 |

9.50 8.30 |

7.60 |

| 4 | 115.80 115.45 |

19 | 103.8 100.7 |

10.70 9.35 |

8.55 |

| NPS | B | J | D | C | G |

| Socket Bore |

Depth Socket |

Bore DIA |

Socket WT |

Body WT |

| NPS | Center to bottom of socket A |

|

| 90° | 45° | |

| 1/2 | 15.5 | 11.5 |

| 3/4 | 19.5 | 12.5 |

| 1 | 22 | 14 |

| 1¼ | 27 | 17 |

| 1½ | 32 | 21 |

| 2 | 38 | 25 |

| 2½ | 41.5 | 29 |

| 3 | 57.5 | 31.5 |

| 4 | 66.5 | 41.5 |

| NPS | 90° | 45° |

| Center to bottom of socket A |

||

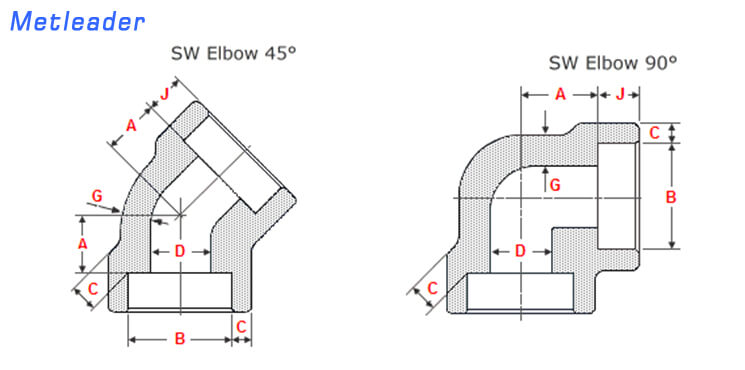

Carbon steel socket elbow 45 degree and 90 degree 6000BL

| NPS | Socket Bore |

Depth Socket |

Bore DIA |

Socket WT |

Body WT |

| B | J | D | C | G | |

| 1/2 | 21.95 21.70 |

10 | 12.5 11 |

5.95 5.20 |

4.80 |

| 3/4 | 27.30 27.05 |

13 | 16.3 14.8 |

6.95 6.05 |

5.55 |

| 1 | 34.05 33.80 |

13 | 21.5 19.9 |

7.90 6.95 |

6.35 |

| 1¼ | 42.80 42.55 |

13 | 30.2 28.7 |

7.90 6.95 |

6.35 |

| 1½ | 48.90 48.65 |

13 | 34.7 33.2 |

8.90 7.80 |

7.15 |

| 2 | 61.35 61.10 |

16 | 43.6 42.1 |

10.90 9.50 |

8.75 |

| NPS | B | J | D | C | G |

| Socket Bore |

Depth Socket |

Bore DIA |

Socket WT |

Body WT |

| NPS | Center to bottom of socket A |

|

| 90° | 45° | |

| 1/2 | 19.5 | 12.5 |

| 3/4 | 22.5 | 14.5 |

| 1 | 27 | 17 |

| 1¼ | 32 | 21 |

| 1½ | 38 | 25 |

| 2 | 41 | 29 |

| NPS | 90° | 45° |

| Center to bottom of socket A |

||