45 degree steel pipe elbow

What is 45 degree steel pipe elbow?

45 degree elbow is to change pipe direction by 45 degree, it is the second common type applied in the industrial pipelines. There two types of 45 degree elbow according to different radius.

-

45 degree LR steel elbow

This kind of elbow is installed between two pipes so that the direction could be changed at an angle of 45 degrees. Since it creates lower frictional resistance, pressure also be lower.

-

45 degree SR elbow

45 degree SR elbow is also called 30 degree steel elbow. Its radius is short than LR elbow. It is just used for some places that the bending is not standard. And it is generally used for low pressure pipe lines or the places used 90 degree pipe elbow limited.

The material of carbon steel 45 degree pipe elbow:

If the standard is ASME B16.9 the material is ASTM A234 WPB for general use. For some special purposes such as low temperature pipes should adopt A420 WPL6 and oil&gas pipes should adopt A860 WPHY42, 52, 60 etc these materials not only belong to low alloy steel but also belong to carbon steel. If the standard is DIN the material refers ST37.2. And for JIS standard the material should be SS400. Except for ASME, DIN, JIS there are many other standards such as EN, GOST and so on.

The specification of carbon steel 45 degree pipe elbow:

The size is generally from 1/2 inch to 60 inch including seamless and seam. 1/2 inch to 24 inch is seamless and 26 inch to 60 inch is weld. The wall thickness refer to SCH10, SCH20, SCH30, STD, SCH40, SCH60, XS, SCH80, SCH100, SCH120, SCH140, SCH160, and XXS. STD and XS are the most popular. The following are the exact specification of some items.

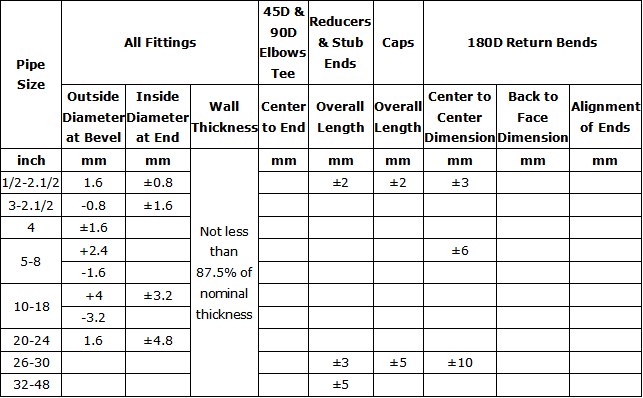

The tolerance of carbon steel 45 degree pipe elbow:

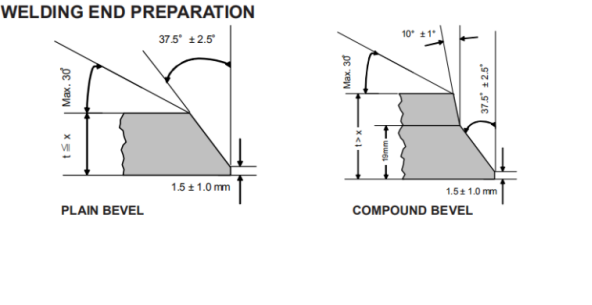

In standard ASME B16.9, the degree of bevel end is 37.5+/-2.5 for the wall thickness is lower than 22mm, and when the wall thickness is more than 22mm the bevel end should be compound bevel commonly known as “W” bevel. The tolerance of wall thickness is +/-12.5mm.

How to choose good quality seamless 45 degree pipe elbow? Some important points need to be paid attention.

1.The raw material must be new steel pipes. Generally the surface of elbows is more smooth than old raw material. Metleader always choose new steel pipes to produce pipe fittings.

2.Inspection is very important. It is a key chain to get good quality. Our company has established a system to inspect each production process daily try the best to make sure good and stable quality.

3.Strength packaging suitable for sea transport to avoid the goods damage. We usually choose strengthen plywood pallet and case to delivery carbon steel elbows.

Delivery period: 10-15 days for LCL, 25-45days for FCL.

Our certificates: ISO9001-2015, BV certificate, OHSAS18001-2007, ISO14001:2015, CE certificate, and ABS certificate.

Leave a Reply