Process and time limit of 3pe anticorrosive steel pipe

From the 1960s to the present, more stringent standards have been put in place for the characteristics of corrosion resistant layers in view of the extreme ecological environments encountered in pipeline construction.

Therefore, in the research of pipeline anticorrosive materials, we should vigorously develop composite materials or composite structures, and pay attention to the anticorrosive layer should have excellent dielectric properties, process properties, stable chemical characteristics and broad temperature applicability, so as to complete various characteristics

For example, anti-corrosion, insulation, heat preservation and improve strength, winding multi-layer PE polyethylene anti-corrosion layer from Europe has been introduced into domestic use for many years.

In recent years, the manufacturing and paving of Hebei 3PE anti-corrosion layer steel pipe has also been gradually completed. With the increase of pipeline burying time, 3PE anti-corrosion layer reflects the disconnection situation dominated by negative electrode disconnection, which is caused by the existence of defects of the anti-corrosion layer itself and the interference of external elements

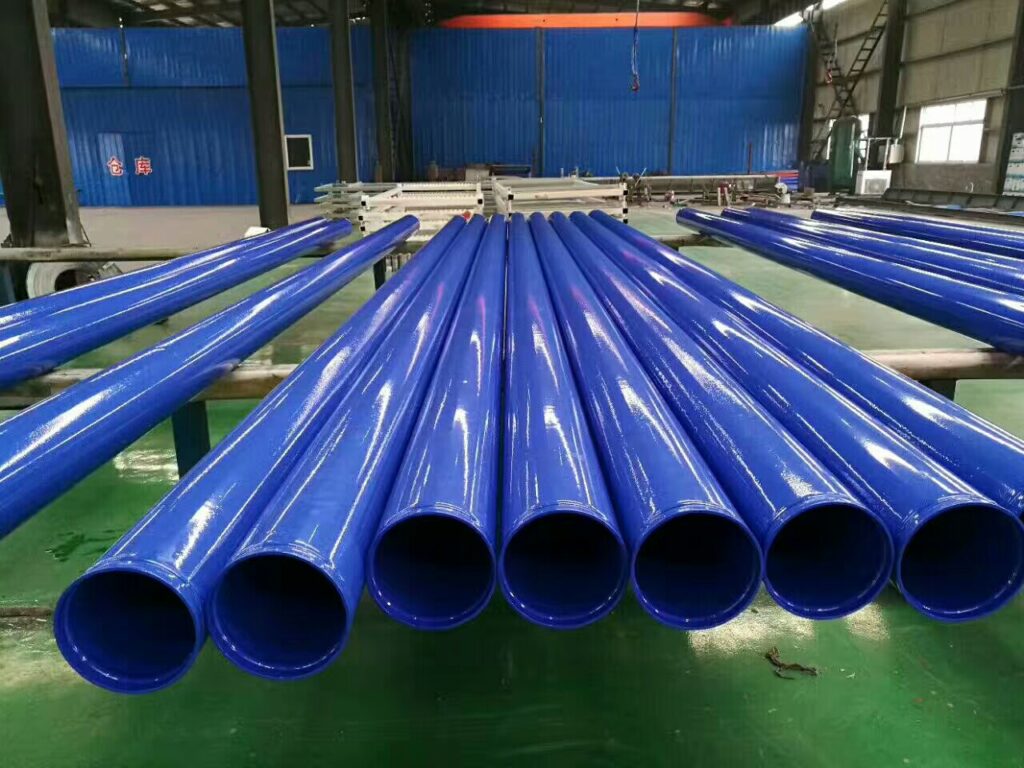

At home and abroad, it has not been pointed out that the large potential difference of 3PE coated steel pipe cathodic protection, and the detection process of buried pipe without excavation is not very sound. 3PE anticorrosive steel pipe base material involves seamless pipe, spiral pipe and straight seam pipe.

The manufacturing process of 3PE anticorrosive steel pipe

3PE anti-corrosion layer is usually used to induce electricity with epoxy powder, which can be directly smeated on the outside of the steel pipe. Its function is to produce chemical bonding with copolymer adhesives, which has excellent corrosion resistance and anti-negative electrode detachment characteristics. The middle layer is a copolymer adhesive, which plays the function of bonding with the epoxy powder at the bottom and the polyethylene protective layer outside.

It has excellent chemical adhesion with the bottom of epoxy powder, which can resist the shear force caused by soil activity and temperature change. Outside is a high density polyethylene protective layer, with excellent moisture resistance, can maintain the epoxy powder bottom and adhesive layer, this multi-layer structure has chemical corrosion resistance and excellent impact resistance characteristics.

What is the service life of Hebei 3pe anticorrosive steel pipe

The service life of Hebei 3pe anticorrosive steel pipe can still be as high as 50 years. We are very cautious about the pipeline laying in Hebei. If you want to know more about steel pipe, you can consult our customer service